ProGator™ 2030A GPS

PrecisionSprayer

- 21-hp, 3-cylinder, liquid-cooled diesel engine

- AutoTrac™ Guidance System

- Indivdual nozzle control

- StarFire 6000 receiver, latest in signal processing technology

- Easy to learn 4640 Universal Display

- 21-hp, 3-cylinder, liquid-cooled diesel engine

- AutoTrac™ Guidance System

- Indivdual nozzle control

- StarFire 6000 receiver, latest in signal processing technology

- Easy to learn 4640 Universal Display

- 21-hp, 3-cylinder, liquid-cooled diesel engine

- AutoTrac™ Guidance System

- Indivdual nozzle control

- StarFire 6000 receiver, latest in signal processing technology

- Easy to learn 4640 Universal Display

- 21-hp, 3-cylinder, liquid-cooled diesel engine

- AutoTrac™ Guidance System

- Indivdual nozzle control

- StarFire 6000 receiver, latest in signal processing technology

- Easy to learn 4640 Universal Display

Features

5.5-m (18-ft) boom

5.5-m (18-ft) boom

When purchasing a John Deere GPS PrecisionSprayer unit, there will be one boom option to choose from, the 5.5-m (18-ft) spray boom.

This boom size makes an excellent choice for spraying greens, fairways, tees, and other areas. Features include:

-

Standard electrohydraulic lift

-

Standard triple-nozzle bodies

-

Bidirectional breakaway

The boom height is adjustable by loosening four U-bolts, lifting or lowering the boom to the desired height, and retightening. This allows both booms to accept a wide range of nozzle angles and styles for proper overlap.

Nozzle spacing

The nozzle spacing on both booms is preset to 50.8 cm (20 in.), but is adjustable by loosening the nozzle body clamp, sliding the nozzle body along the boom, and re-tightening it into position.

The 5.5-m (18-ft) boom has four nozzles on the left boom, three nozzles on the center boom, and four nozzles on the right boom.

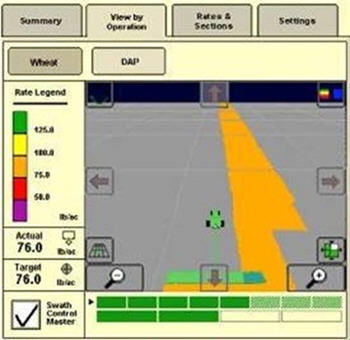

4640 Universal Display

4640 Universal Display

The 4640 Universal Display provides the latest redesign and improved operating experience for John Deere ProGator™ GPS Sprayer operators, and is loaded with the following benefits:

- A quickly learnable display resulting in reduced training, less expensive downtime, and fewer operator mistakes

- Improved data capture and collection capabilities, providing more accurate Section Control (individual nozzle control) performance and documentation

- An expanding suite of precision spraying applications including performance and usability enhancements in applications such as the AutoTrac™ assisted steering system and Section Control and documentation

Spraying with Section Control

Spraying with Section Control

John Deere Section Control (individual nozzle control) automatically turns individual nozzles on or off to reduce overlap and improve input management. John Deere Section Control can be utilized for spraying greens, tees, fairways, and roughs when adequate signal is available.

Automatically control individual nozzles

John Deere Section Control

John Deere Section Control

John Deere Section Control (formerly known as Swath Control Pro™ software) is a software activation on the 4640 Universal Display. John Deere Section Control automatically controls the nozzles on a sprayer by allowing individual nozzles to turn off and turn on when required.

When John Deere Section Control is enabled, it utilizes global positioning system (GPS) information to turn nozzles on and off and reduce overlap in previously applied areas. It also can be used to reference interior and exterior field boundaries. John Deere Section Control automatically controls the nozzles as the ProGator™ GPS PrecisionSprayer passes through defined boundaries.

John Deere individual nozzle control improves efficiency for the golf and sports turf superintendent. One of the primary benefits of individual nozzle control is reduced product overlap while spraying. Overlap reduction decreases the total amount of product used, saving the golf course money by lowering the input costs.

Some turf can be easily harmed by excessive chemical or fertilizer applications that negatively impact the plant health. John Deere individual nozzle control reduces overlap to help avoid over-application.

John Deere individual nozzle control also reduces the stress level of the operator. By utilizing Section Control, the operator does not need to focus on manually turning the boom sections off and on. This helps reduce fatigue and enables the operator run longer hours spraying on the course. It helps less-experienced operators more accurately perform the product application on the course.

John Deere StarFire 6000 Receiver

John Deere StarFire 6000 Receiver

The John Deere StarFire 6000 Receiver is an enhanced replacement for the StarFire 3000 Receiver and expands on the precision agronomic value that golf and sports turf professionals have come to expect from John Deere. The StarFire 6000 Receiver implements an improved antenna, the latest in Global Navigation Satellite System (GNSS) signal processing technology, and an added differential correction signal. All of this technology adds up to improved performance and uptime as well as lower cost of operation when paired with precision systems such as AutoTrac™ assisted steering system and John Deere Section Control (individual nozzle control).

AutoTrac Universal steering kit 300

AutoTrac Universal steering kit 300

The AutoTrac Universal (ATU) 300 steering kit is a machine steering kit used for automatic guidance in John Deere and non-John Deere machines. Pair the machine kit with a complete GreenStar™ system to operate automatic, hands-free guidance in approved machine platforms.

AutoTrac offers many benefits to operators, including optimized machine efficiency, reduced operator fatigue, and the ability to work at faster speeds. The ATU 300 is the premier universal steering system in the golf and sports turf industry.

GreenStar Rate Controller

GreenStar Rate Controller

The GreenStar Rate Controller allows the 4640 Universal Display to integrate the ProGator GPS PrecisionSprayer to accomplish the following:

- Automatic rate control

- Field documentation

- John Deere Section Control (individual nozzle control)

Specs & Compare

Key Specs | ProGator™ 2030A GPS Current Model |

| Maximum speed (standard tires) | 30.7 km/h 19.1 mph |

| Displacement | 1006 cc 61.4 cu in. |

| Horsepower | At 3200 rpm: 16.5 kW 22.1 hp *Engine hp is provided by the mfr for comparison purposes only. Actual operating hp will be less. Refer to engine manufacturer's website for additional information. |

| Maximum gross vehicle weight (4WD with heavy-duty suspension, wide rear tire, and four-post ROPS) | 2841 kg 6264 lb |

| Transmission configuration | Five-speed synchro-mesh with five forward gears and one reverse gear |

| Turning circle clearance (Inside diameter - 2WD) | Raidus: 431.8 mm 17 in. |

Engine | |

| Manufacturer/model | |

| Horsepower | At 3200 rpm: 16.5 kW 22.1 hp *Engine hp is provided by the mfr for comparison purposes only. Actual operating hp will be less. Refer to engine manufacturer's website for additional information. |

| Configuration | 3-cylinder liquid-cooled diesel |

| High idle speed | 3450 rpm |

| Displacement | 1006 cc 61.4 cu in. |

Transmission | |

| Manufacturer | Kanzaki |

| Configuration | Five-speed synchro-mesh with five forward gears and one reverse gear |

| Maximum speed (standard tires) | 30.7 km/h 19.1 mph |

| 4WD options | Manual engage on demand |

Dimensions | |

| Ground clearance (unloaded) | 168 mm 6.6 in. |

| Bed height (loaded) | 832 mm 32.75 in. |

| Wheelbase | 167.6 cm 66 in. |

| Wheel tread, front | 123.2 cm 48.5 in. |

| Wheel tread, rear standard | 129 cm 50.8 in. |

| Width, overall (standard tires) | 158.6 cm 62.4 in. |

| Length, overall (standard tires) | 319.2 cm 125.7 in. |

| Length, overall with box | 328.5 cm 129.3 in. |

| Length, overall without box | 319.2 cm 125.7 in. |

| Height, overall | 193.6 cm 76.25 in. |

Steering | |

| Type | Hydraulic power |

Turning circle clearance | |

| Inside diameter - 2WD | Raidus: 431.8 mm 17 in. |

| Inside diameter - 4WD | Radius: 1752 mm 69 in. |

Capacities | |

| Maximum gross vehicle weight(includes 200-lb operator, 200-lb passenger, loaded attachment) | 2WD with standard suspension 2449 kg 5400 lb 4WD with standard suspension 2449 kg 5400 lb 2WD with heavy-duty suspension, wide rear tire, and four-post ROPS 2841 kg 6264 lb 4WD with heavy-duty suspension, wide rear tire, and four-post ROPS 2841 kg 6264 lb |

| Base machine weight (no passenger, no operator, no loaded attachment, full fluids) | 2WD with standard suspension 856 kg 1887 lb 4WD with standard suspension 915 kg 2017 lb 2WD with heavy-duty suspension, wide rear tire, and four-post ROPS 912 kg 2010 lb 4WD with heavy-duty suspension, wide rear tire, and four-post ROPS 971 kg 2140 lb |

| Payload capacity (includes 200-lb operator, 200-lb passenger, and loaded attachment) | 2WD with standard suspension 1594 kg 3514 lb 4WD with standard suspension 1535 kg 3384 lb 2WD with heavy-duty suspension, wide rear tire, and four-post ROPS 1930 kg 4255 lb 4WD with heavy-duty suspension, wide rear tire, and four-post ROPS 1871 kg 4125 lb |

| Cargo box internal dimensions | Length 165 cm 65 in. Width 128.3 cm 50.5 in. Height 26.7 cm 10.5 in. |

| Towing capacity (rear hitch) | 907 kg 2000 lb |

| Fuel capacity | 30.3 L 8 U.S. gal. |

Tires | |

| Front standard | 23x10.50-12 (4 PR) |

| Rear standard | 26x12.00-12 (4 PR) |

| Wide rear tire option | 26x14.00-12 (4 PR) |

Suspension | |

| Front | Dual leaf springs and shocks |

| Rear | Dual leaf springs and shocks |

Brakes | |

| Type | 4-wheel hydraulic drum |

Battery | |

| Type | 500 CCA 12 V |

Alternator | |

| Size, amp | 55 amp |

Sound level | |

| At operator's ear | 86 dBA |

| Measuring standard | ISO 11201 |

| Attachments installed | Cargo box |

Certifications | |

| Type | CARB ASME B56.8a-1994, OSHA12928.51CSA |

Additional information | |

| Date collected |