260B

Backhoe

- Large, easy-access step and hand brace

- Upgraded valve provides smooth hydraulics for precise control

- Available field-install thumb option

- Stabilizer, boom and swing locks accessible from the operator’s seat

- Large, easy-access step and hand brace

- Upgraded valve provides smooth hydraulics for precise control

- Available field-install thumb option

- Stabilizer, boom and swing locks accessible from the operator’s seat

- Large, easy-access step and hand brace

- Upgraded valve provides smooth hydraulics for precise control

- Available field-install thumb option

- Stabilizer, boom and swing locks accessible from the operator’s seat

- Large, easy-access step and hand brace

- Upgraded valve provides smooth hydraulics for precise control

- Available field-install thumb option

- Stabilizer, boom and swing locks accessible from the operator’s seat

Features

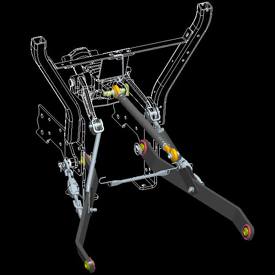

260B Backhoe on a 1025R Tractor

260B Backhoe on a 1025R Tractor

Move piles of brush with 260B Backhoe

Move piles of brush with 260B Backhoe

The 260B Backhoe was designed to have best-in-class features priced competitively with the various backhoes in its class in the marketplace. Competitive units were tested and benchmarked to ensure that John Deere provided the right product at the right price.

The following list is a high-level overview of the features that are discussed throughout this content:

Mid-mower deck compatible to allow for compounding of equipment to save operator's time

Durable subframe, which gives strength and rigidity to the tractor frame and transmission

Protective rubber boots on backhoe controls

Tool-free installation/removal in a matter of minutes (once initially installed)

20-cm (8-in.), 31-cm (12-in.), and 41-cm (16-in.) trenching bucket choices with bolt-on, replaceable digging teeth, as well as a ripper option

Optional kits such as rubber street pads for stabilizer feet

Optional mechanical and hydraulic backhoe thumb available to lift heavy logs and piles of brush

Lift heavy logs with 260B Backhoe

Lift heavy logs with 260B Backhoe

The 260B Backhoe has been designed with maximum operator comfort in mind. The features listed below will keep the operator comfortable all day long when working on various projects.

- A strong 3-point stance can be maintained when mounting and dismounting the backhoe using the rollover protective structure (ROPS) grab handle, the console grab handle, and the large boarding step mounted to the stabilizer arm.

Stabilizer arm on 260B Backhoe

Stabilizer arm on 260B Backhoe

- High-back seat provides more operator comfort during longer work hours.

High-back seat provides comfortable operation

High-back seat provides comfortable operation

- Stabilizers, boom and swing locks are accessible from the operator’s seat and have a built-in storage location when the backhoe is in use.

- Operator platform with non-slip grips are provided.

- All controls are in an ergonomically comfortable position and are easily reachable from within the operator platform when in the backhoe position.

260B Backhoe

260B Backhoe

The 260B Backhoe is designed so the backhoe can be removed in under 5 minutes with no tools needed (once initially installed). Instructions are also conveniently placed on the rear of the backhoe to assist with installing and removing the backhoe. The instructions below are an abbreviated version of what can be found in the operator's manual for installation and removal.

NOTE: The instructions below are for reference only and should not be used for actual installing and removing the backhoe. The operator's manual gives a more complete and proper set of instructions.

Installation

-

Back up tractor to within 20 cm (8 in.) from backhoe

-

Park tractor

- Connect power beyond system

-

Remove backhoe boom-lock pin

-

Back tractor closer to backhoe and use backhoe control levers to align backhoe frame with backhoe mounts on tractor

-

Use stabilizer controls to raise and lower stabilizers as needed to position notches in backhoe frame above mount hooks

-

Use stabilizers to lower hooks on notches on the back of tractor

-

Use boom control to raise boom into back of tractor and install pins to secure backhoe to tractor

-

- Use pins to secure backhoe to tractor

- Machine is now ready for use

Removal

-

Lower stabilizers to a few inches from the ground

-

Center boom and install swing-locking pin

-

Remove boom-locking pin if installed

-

Extend dipper stick and lower boom

-

Rotate bucket until top edge is parallel with ground

-

Use boom control lever to lower and place slight down pressure on backhoe

-

Remove pins from backhoe mounts

-

Use backhoe controls to lower backhoe toward the ground

-

Use stabilizer controls to lift backhoe off lower mounting notches

-

Lower backhoe to ground

-

Disconnect hydraulic hoses and close connection on the tractor and backhoe side

-

Drive away for tractor use

Change between 3-point hitch and backhoe

3-point hitch

3-point hitch

Removal of the 3-point hitch components is required for the 260B Backhoe installation. The entire 3-point hitch is easily removed. No special tools or adjustments are needed.

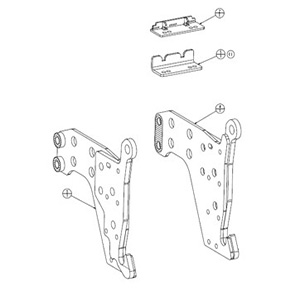

Subframe

Subframe mounting bundle (BXX10279)

Subframe mounting bundle (BXX10279)

The subframe provides strength to the tractor frame and transmission housing to ensure the integrity of the tractor is not compromised by the forces generated by the backhoe.

The subframe is fully mid-mower deck compatible, regardless of which mower lift system is used. Please see that section of the Sales Manual for more details.

NOTE: Tire chains are not compatible with backhoe subframe installed.

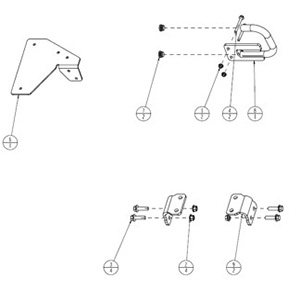

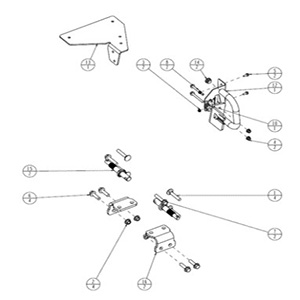

Grab handles

Grab handle kit (BXX10278)

Grab handle kit (BXX10278)

Grab handle kit (BXX10322)

Grab handle kit (BXX10322)

Grab handle kit (BXX10323)

Grab handle kit (BXX10323)

Grab handles provide the operator with extra support when getting on and off the backhoe.

Power beyond hydraulics

Power beyond hydraulics (1026R Tractor shown)

Power beyond hydraulics (1026R Tractor shown)

Power beyond hydraulics are required on the tractor to run the 260B Backhoe as the kit provides continuous flow to the backhoe.

The power beyond kit for the tractor is not included in the sub-frame attachment and needs to be ordered separately.

The 260B Backhoe uses two different pins for locking out the swing frame and boom for safe transportation or storage. These pins can be quickly removed and stored in the operator platform so they are not accidentally misplaced while using the backhoe.

20-degree ramp angle for easy transport

20-degree ramp angle for easy transport

The 260B Backhoe has a ramp angle of 20 degrees, which allows for easy transportation on most trailers. This level of ramp angle also makes for better maneuverability across land that is uneven such as a ditch or trench.

Note the line that moves up from the low point of the boom and how it is in line with the bucket when in the storage position. Compared to the competitive units that are in the marketplace, the transport configuration of the 260B Backhoe allows the backhoe to not have to move when going through a ditch or other uneven terrain.

260B Backhoe

260B Backhoe

The 260B Backhoe is fully mid-mower deck compatible. The sub-frame for the backhoe will not interfere with the mower or mower deck linkage, regardless of which mower deck lift system is used.

This feature keeps operators more productive as the mid-mower deck does not have to be removed in order to go out and do backhoe work. It is not recommended to use the mower deck with the backhoe installed due to the extra ground compaction and length of the tractor.

The mechanical mower lift linkage will allow the mower to be raised and lowered with the 3-point hitch removed and the 260B Backhoe attached.

Enclosed boom and dipper

Enclosed boom and dipper

The boom and dipper are designed with the strength to handle all the necessary loads this backhoe can generate. The boom, dipper, and bucket cylinders are run externally on the 260B Backhoe. This provides easy access for servicing and maintenance.

The fully enclosed boom on the 260B Backhoe measures a full 16.5 cm (6.5 in.) at the base and the dipper stick measures 13.9 cm (5.5 in.) at its widest point. These components are larger than competitive backhoes, which gives the 260B Backhoe a more durable structure and a bigger, heavy-duty appearance.

The 260B Backhoe was designed with a continuous boom structure rather than a multiple-piece boom that is welded together with side plates some competitors use. This continuous boom provides a more rigid, stronger structure with less weld points that could potentially fail.

Cylinders

Cylinders

All cylinders on the 260B Backhoe are fully serviceable; should there be any problems, the cylinders can be taken apart and rebuilt without having to replace the whole cylinder. This saves the operator money should they damage a cylinder through improper removal of concrete, rocks, or tree roots. The boom and dipper cylinders are equipped with circuit relief to protect the cylinder rods during these high-stress activities.

The internal seals on these cylinders are the same high-quality, durable seals that are used on some of the larger backhoes available from John Deere.

The boom cylinder on the 260B Backhoe is designed with an internal cushion to ensure the cylinder does not come to an abrupt stop at the end of the stroke. This feature is appreciated by novice operators learning to use their backhoe or for the experienced when working in and around delicate surroundings, such as a fence or landscaping.

406-mm (16-in.) bucket shown

406-mm (16-in.) bucket shown

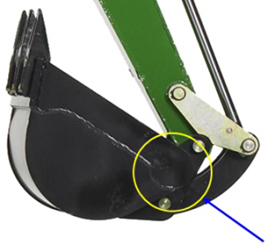

Heavy-duty roll tube for extra strength

Heavy-duty roll tube for extra strength

The 260B Backhoe has buckets available in 203-mm (8-in.), 304-mm (12-in.), and 406-mm (16-in.) digging widths. These buckets are designed to be matched with the backhoe for great performance. All buckets have massive, replaceable, bolt-on digging teeth, great for digging out rocks, concrete, and tree roots. The 203-mm (8-in.) bucket has two digging teeth and the 304 mm (12 in.) and 406 mm (16 In.) have three teeth on them.

The buckets are designed with a large, heavy-duty roll tube, highlighted in the picture above on the right. This large tube ensures the bucket has the strength to handle all the tough situations in which the backhoe will be used.

178-mm (7-in.) trenching bucket

178-mm (7-in.) trenching bucket

Bucket specifications

|

203-mm (8-in.) bucket |

304-mm (12-in.) bucket |

406 mm (16 in.) |

178-mm (7-in.) trenching bucket |

SAE struck capacity |

0.011 m3 (0.42 cu ft) |

0.019 m3 (0.66 cu ft) |

0.025 m3 (0.9 cu ft) |

0.0045 m3 (0.16 cu ft) |

Heaped capacity |

0.013 m3 (0.46 cu ft) |

0.022 m3 (0.76 cu ft) |

0.03 m3 (1.06 cu ft) |

0.0057 m3 (0.2 cu ft) |

Shipping weight |

17 kg (38 lb) |

22 kg (49 lb) |

27 kg (59 lb) |

16.2 kg (35.8 lb) |

NOTE: These buckets are designed to work with only the backhoe specified and will not work with any other John Deere backhoes.

BXX10248 backhoe hydraulic thumb kit

BXX10248 backhoe hydraulic thumb kit

BLV10750 backhoe mechanical thumb kit

BLV10750 backhoe mechanical thumb kit

BXX10247 backhoe ripper tooth

BXX10247 backhoe ripper tooth

BLV10986 rubber street pad kit

BLV10986 rubber street pad kit

Specs & Compare

Key Specs | 260B Current Model |

| Digging depth | 1.9 m 6 ft, 2 in. |

| SAE dipperstick digging force | 5280 N 538 kg 1187 lb |

| SAE bucket digging force | 9056 N 924 kg 2036 lb |

| Swing arc | 150 degree (angle) |

| Boom lift capacity | 129 kg 285 lb |

| Transport height | 1.7 m 6 ft, 6 in. |

| Stabilizers spread width, up | 1.5 m 4 ft, 10 in. |

| Stabilizers spread width, down | 1.9 m 6 ft, 2 in. |

| Bucket widths | 0.2 m (8 in.) 0.3 m (12 in.) 0.4 m (16 in.) |

| Total weight | |

Backhoe | |

| Swing arc | 150 degree (angle) |

| Bucket rotation | 180 degree (angle) |

| Boom lift capacity | 129 kg 285 lb |

| SAE dipperstick digging force | 5280 N 538 kg 1187 lb |

| SAE bucket digging force | 9056 N 924 kg 2036 lb |

| Angle of departure | 20 degree (angle) |

| Hydraulic relief setting | |

| Bucket control main relief valve pressure | |

Dimensions | |

| Digging depth | 1.9 m 6 ft, 2 in. |

| Loading height (bucket at 60 degrees) | 1.5 m 5 ft |

| Reach from center line of swing pivot | 2.6 m 8 ft, 8 in. |

| Transport height | 1.7 m 6 ft, 6 in. |

| Loading reach (bucket at 60 degrees) | 0.8 m 2 ft, 9 in. |

| Transport overhang | 0.9 m 3 ft, 1 in. |

| Undercut | 0.4 m 1 ft, 5 in. |

| Stabilizer type | Stabilizers spread width, up 1.5 m 4 ft, 10 in. Stabilizers spread width, down 1.9 m 6 ft, 2 in. Hydraulic |

Weight | |

| Total | |

| With RSA side plate kit and 20-in. bucket | |

| With frame adapter and 24-in. bucket | |

| With medium frame adapter and 24-in. bucket | |

| With large frame adapter and 24-in. bucket | |

| With 0.4-m (16-in.) bucket | 277 kg 610 lb |

Bucket | |

| Bucket widths | SAE struck capacity 0.2 m (8 in.) - 0.011 m3 (0.42 cu ft) 0.3 m (12 in.) - 0.019 m3 (0.66 cu ft) 0.4 m (16 in.) - 0.025 m3 (0.9 cu ft) Heaped capacity 0.2 m (8 in.) - 0.013 m3 (0.46 cu ft) 0.3 m (12 in.) - 0.022 m3 (0.76 cu ft) 0.4 m (16 in.) - 0.03 m3 (1.06 cu ft) Shipping weight 0.2 m (8 in.) - 17 kg (38 lb) 0.3 m (12 in.) - 22 kg (49 lb) 0.4 m (16 in.) - 25 kg (55 lb) 0.2 m (8 in.) 0.3 m (12 in.) 0.4 m (16 in.) |

Additional information | |

| Date collected |