5120ML

Low-Profile Utility Tractor

- 118 hp John Deere PowerTech™ engine

- Up to 3 Transmission Options

- Connected with JDLink™

- Open Operator’s Station or Cab Option

- As narrow as 61 in. working width (5ML Narrow Cab)

- 118 hp John Deere PowerTech™ engine

- Up to 3 Transmission Options

- Connected with JDLink™

- Open Operator’s Station or Cab Option

- As narrow as 61 in. working width (5ML Narrow Cab)

- 118 hp John Deere PowerTech™ engine

- Up to 3 Transmission Options

- Connected with JDLink™

- Open Operator’s Station or Cab Option

- As narrow as 61 in. working width (5ML Narrow Cab)

- 118 hp John Deere PowerTech™ engine

- Up to 3 Transmission Options

- Connected with JDLink™

- Open Operator’s Station or Cab Option

- As narrow as 61 in. working width (5ML Narrow Cab)

Features

5ML Cab Tractor

5ML Cab Tractor

Building off the esteemed reputation of the 5ML tractor series, John Deere is now offering the 5ML with a factory-installed cab. This cab has been specially designed to be used in high value crop operations such as orchards and vineyards. Long, hot harvest days are more comfortable with the ergonomically designed cab featuring ample operator space, sleek right-hand console, air suspension seat, and an adjustable steering wheel. To ensure a comprehensive operator experience, controls are common throughout the 5 Series tractor portfolio. Limit tree canopy interference with the low-profile stance and optional limb lifters. By offering a narrow axle from the factory, the tractor opportunities have been widened.

- John Deere designed and factory-installed cab on 5ML tractor

- Save time by ordering factory installed cab versus adding an aftermarket cab

- Stay on track using AutoTrac™ guidance options

- Reduce operator fatigue with ergonomic right-hand controls

- Minimize crop interference thanks to the low-profile tractor

- Fits a variety of crop types with narrow axle offering

- Reduce training time for new operators by having common controls throughout 5 Series portfolio

- Damage to doors and windows is prevented by shielding around doors, reinforced glass, and integrated door handle

Enhanced shielding and integrated door handle

Enhanced shielding and integrated door handle

Easy to reach right hand controls

Easy to reach right hand controls

Charging ports and storage

Charging ports and storage

Utilize StarFire™ receiver and Gen 4 display

Utilize StarFire™ receiver and Gen 4 display

Heat and air conditioning controls

Heat and air conditioning controls

Optional Bluetooth® Radio

Optional Bluetooth® Radio

Bluetooth is a trademark of Bluetooth SIG, Inc.

5ML with narrow axle

5ML with narrow axle

5ML with standard axle

5ML with standard axle

No matter your row width, the 5ML can be configured to best fit into your operation. While working in orchards, the standard axle provides a powerful stance and presence. Fit into vineyards without compromising on technology or comfort by equipping the tractor with the narrow axle.

- Fit down tight rows by narrowing the tractor width to 5.25 ft (1.6 m)

- Capable of working in most orchards and vineyards

- The narrow axle option unlocks a new customer segment for the 5ML series

Additional Details:

When the tractor is ordered with the narrow axle, a “Narrow” decal will be added to the hood.

5120ML Narrow decal

5120ML Narrow decal

Setting up AutoTrac™ Basic on the digital dash display

Setting up AutoTrac™ Basic on the digital dash display

Government and environmental pressures, including public perception, are increasing the need for technology and data collection. The 5ML Cab tractor has the most technology offered in a John Deere high value crop tractor. Efficiently manage employees, crops, and data by adding a Gen 4 Display, StarFire™ receiver, and activating an AutoTrac™ subscription. Spend less time manually inputting records and more time growing a healthy crop by collecting data during each pass.

- Minimize skipped rows and operator error by equipping the tractor with a Gen 4 Display and a StarFire receiver

- Reduce operator fatigue by engaging AutoTrac guidance

- Streamline repetitive tasks, such as making headland turns or tillage work, by using iTEC™ Basic (Intelligent Total Equipment Control)

- View real time machine location and information utilizing JDLink™ offered in base from the factory

- Enhance job tracking data when working with ISOBUS compatible implements

iTEC Basic with almond conditioning

iTEC Basic with almond conditioning

StarFire Universal Receiver

StarFire Universal Receiver

PowrQuad PLUS™ or Powr8™ transmissions

PowrQuad PLUS™ or Powr8™ transmissions

Effortlessly find the right working speed for the job with simple push-button gear shifting. A more productive transmission is found on the PowrQuad PLUS™ and Powr8™ transmissions which use clutchless hydraulic shifting between forward and reverse.

- Ergonomically placed transmission control lever allows the operator to change gears and ranges using one lever

- Enhances operator efficiencies by reducing steps to change gears

- Effortlessly switch directions using the electrohydraulic fingertip directional lever, ideal in applications that require frequent directional changes in tight spaces

- Eliminates wear on the clutch by automating gear shifts at the push of a button

Single lever for gears and rangest

Single lever for gears and rangest

Creeper gear lever

Creeper gear lever

Utilizing a 1000-gallon air blast sprayer

Utilizing a 1000-gallon air blast sprayer

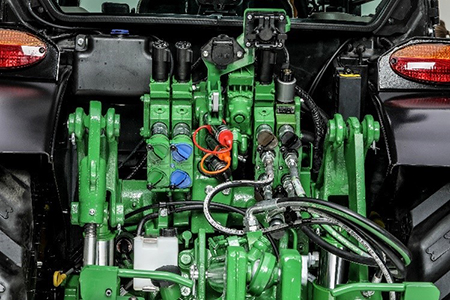

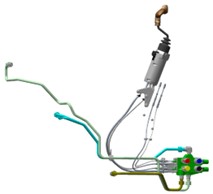

Increase job performance when using hydraulic implements, such as air blast sprayers, with pressure-flow compensated (PFC) hydraulics. Standard on all 5ML cab tractors, PFC hydraulics provide better hydraulic performance and cooling capacity when running large implements.

- In standby mode, the PFC system is more efficient than a comparable open-center system because the hydraulic power is only provided when needed

- Improved fuel efficiency by reducing engine power when it is not needed

- Enhanced oil cooling when using hydraulically demanding implements

- Reduced hydraulic noise levels

Triple rear SCVs standard

Triple rear SCVs standard

Optional 4th Rear SCV as field install kit

Optional 4th Rear SCV as field install kit

Optional Triple Mid EH SCVs

Optional Triple Mid EH SCVs

5EN mowing in vineyardt

5EN mowing in vineyardt

5ML spraying in orchard

5ML spraying in orchard

While working in your orchard or vineyard, getting in and out the rows effortlessly is important. Turning radius is a top priority for high value crops growers and was a top priority when designing our high value crops tractors.

- Efficiency gains when making turns in and out of rows

- Worry less about making tight headland turns

Right-hand fender shield and low-profile seat

Right-hand fender shield and low-profile seat

Overview

The standard OOS on 5ML Tractors was designed for low-clearance applications. It features a low-profile seat, a smaller-diameter steering wheel, protected controls, and a low-profile, rear-mounted rollover protective structure (ROPS). Rounding off these standard features and incorporated into each operator platform is a shield which limits heat transfer from the hydraulics to the operator.

Benefits

- Ability to drive under low-clearance areas

- Visibility of the front of the tractor with a sloping hood

- Conveniently located operator controls within arms’ reach on the right-hand console control pod

- Protect control pod from low-hanging crops with the right-hand fender shield

Additional details

All the most crucial operator controls are conveniently located within arms’ reach on the right-hand console control pod. The engine throttle control, selective control valve (SCV) levers, power take-off (PTO) engagement, and hitch-lift control levers are grouped together. On the 5ML, this control pod is positioned on the right-side fender, protected from low-hanging crops by a shield.

Color-coded bands on the SCV levers correspond with the color on the rear SCVs, making it easy for any operator to determine which lever operates which rear SCV.

The 5ML Tractor also offers optional fender extensions to minimize crop disturbance, especially in orchards or tree nut applications. Two fender extension options are available to meet varying tire sizes and coverage preferences.

The foldable ROPS on the 5ML Tractor has a unique design and is 15.2-cm (6-in.) lower at maximum height than the standard 5M Tractors.

The shifter linkages are tighter to offer a more accurate shift pattern, which translates to a crisper throw between gears. Incorporating technology found on standard 5M Tractors, the 5ML now offers a declutch button, enabling the operator to shift gears within a range without the use of the foot clutch.

5ML Tractors also include the following features:

- Retractable seat belts

- Rear certified ROPS for OOS tractors

- Heat shield limiting hydraulic heat passed onto the operator Key-switch interlock prevents bypass starting

- Audible and visual PTO warning alerts when the operator leaves the seat with the PTO engaged

- Positive park position prevents the tractor from moving when the engine is off

- Four amber turn-signal/flashing warning lights for road transport (these are break-away) Slow-moving vehicle (SMV) sign alerts other road users during transport

- Safety decals keep safety in the minds of new and experienced operators

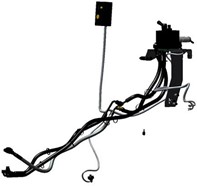

- Left- and right-hand steps provide easy and convenient access from both sides of the tractor Fuel system is fully grounded to meet safety and fuel fill regulation requirements

- For convenience of operation, the fuel and diesel exhaust fluid (DEF) fill are both on the same side with clearly marked and color-coded caps. The DEF tank has a capacity of 12.1-L (3.2-gal.), which is more than enough to sustain proper tractor operation and fuel treatment for more than one full tank of diesel. A field-installed lockable fuel cap is offered for protection and peace of mind.

Transmission controls on PowrReverser™ transmission models:

Gear and range shift levers are located to the right of the operator. The gear lever incorporates a declutch button enabling the operator to shift gears without the use of the foot clutch. Unique knobs also make it easier to distinguish between the two.

Gear lever with declutch button

Gear lever with declutch button

Transmission controls on PowrQuad™ transmission models:

A single transmission control is located to the right of the operator. This control features the ability to shift through gears within a range using the rabbit button to increase gears and the turtle button to decrease gears. A range change can be completed with this control, as well by moving through A-D ranges similar to a traditional range controller. To aide in ease of operation, operators can use the integrated declutch button rather than the foot clutch to change ranges.

Transmission control on PowrQuad transmission models

Transmission control on PowrQuad transmission models

A foot throttle with a platform pedal is located on the right side of the operator. The pedal is positioned for ease of use, yet does not clutter the floor. The hand throttle is easily accessible on the right hand console.

Engaged by either foot, the differential lock pedal is placed on the floor.

Differential lock button

Differential lock button

When the tractor is used in applications requiring the clutch and brake pedals to be used frequently, the operator will see the benefit of the suspended pedals.

The electrohydraulic forward/reverse direction lever is located on the left-hand side of the instrument console, connected to the steering column. There is also a guard for the reverser lever. Operated with the left-hand finger, the right hand is free to simultaneously run the loader, hitch, or hand throttle.

Left hand reverser with guard

Left hand reverser with guard

3-point hitch controls

Mechanical hitch controls are available on models equipped with a PowrReverser transmission, while models equipped with a PowrQuad transmission will have an electrohydraulic (EH) hitch. With an EH hitch, operators will have the functionality to raise and lower the hitch from the rear left-hand fender, reducing time when attaching and detaching implements.

Left-hand fender hitch control

Left-hand fender hitch control

PTO controls and speeds

The 5ML features electrohydraulic PTO engagement on all models.

The push/pull knob on open station tractors is conveniently located beside the hand throttle on the right-hand side of the operator. When the PTO is engaged, a light on the instrument panel will illuminate and PTO speed is indicated by target bars. Models equipped with a PowrReverser transmission have a 540/540E rpm shiftable PTO while models equipped with a PowrQuad transmission have a three-speed PTO, 540/540E/1000 rpm.

Enhancing operator safety, the tractor does not start with the PTO engaged. An alarm sounds if the operator attempts to leave the seat with the PTO engaged. The PTO shaft is protected by a hinged shield.

Hydraulics controls

The color-coded bands on the levers, which control triple rear SCVs, correspond to the color of the dust cap and the SCV valve they control.

Mechanical front-wheel drive (MFWD) controls

All four-wheel drive (4WD) axles are equipped with the engage-on-the-go MFWD. This toggle switch is now located on the right-hand console.

Lighting controls – Multi-position dial

The five-position lighting package is straightforward with the lighting control switch on the right side of the steering column. The switch positions are: off, warning, worklight, transport 1 (warning and high-beam headlights), and transport 2 (warning and headlights). A turn-signal lever is located on the left side of the steering column for quick and easy use.

Overview

Ample speeds and ease of operation for demanding applications with the 16F/16R PowrReverser, providing 16 forward speeds and 16 reverse speeds. This transmission comes standard with a dual speed 540/540 Economy power take-off (PTO), and it is ideal for applications requiring frequent directional changes, such as loader work.

Benefits

- Effortlessly switch directions with a small finger motion using the electrohydraulic fingertip directional lever

- Frees the right hand to operate other tractor controls, such as the loader, rear implements, or throttle, as the directional lever allows the operator to steer and shift direction with the left hand

- Ideal for rear blading and any applications that require frequent directional changes in tight spaces

- Clutch-less hydraulic shifting between forward and reverse

- Lower engine vibration, reduced noise, less wear and tear on the engine, reduced fuel consumption, and increased operator comfort from the standard economy PTO (E-PTO)

Additional details

16F/16R transmission includes:

- Hydraulic wet clutches (forward and reverse)

- Maximize durability and outlast the life of any dry clutch

- When tractors are run by multiple operators with a variety of experience levels, a wet clutch is the best way to maintain transmission integrity and performance while decreasing clutch replacement costs

- Platform-mounted shift levers (four ranges, four gears)

- Two platform-mounted levers offer easy and comfortable shifting for a pleasant operator experience

- The gear-shift lever is easy to reach, and the less-used range lever is shorter. Unique knobs make it easy to distinguish between the two

- Left-hand reverser

- The control is located on the left side of the steering column and selects forward, reverse, and neutral positions

- Constant-mesh helical-cut gears

- Provide quieter operation and excellent reliability while the pressure-lubricated top shaft adds to the transmission durability

- Fully enclosed, rigid shift linkages for short throw and crisp shifts enable all operators to clearly know in what range and gear they are operating

- Pressure-lubricated top shaft

- Positive park pawl: provides positive park and eliminates the need for a hand brake

- Neutral start switch

Gear and range shift levers (cab)t

Gear and range shift levers (cab)t

Gear shift lever open operator’s station (OOS)

Gear shift lever open operator’s station (OOS)

Range shift lever (OOS)

Range shift lever (OOS)

The forward lever selects one of four speeds, all synchronized shifts for on-the-go shifting with the use of the clutch. The rear lever selects ranges A, B, C, or D. All ranges are fully synchronized. When upshifting, operators can move between ranges without stopping the tractor providing convenience for on-the-go shifting from field to transport.

Left-hand reverser lever

Left-hand reverser lever

NOTE: A neutral start switch requires the directional lever be in the neutral position to start the engine.

Integrated declutch button on gear shifter

Integrated declutch button on gear shifter

NOTE: The PowrReverser transmission is not available for the 5130M or 5130ML tractors.

The PowrReverser has a built-in engagement override valve for additional safety. This valve requires the clutch pedal to be depressed one time after each engine start before the transmission will begin to operate normally, giving the operator another opportunity to put all focus on the tractor.

See the PTO functional area for more information on E-PTO.

Creeper lever on 5MH only

Creeper lever on 5MH only

The creeper gears are accessible by engaging the creeper lever into rabbit or turtle position. This provides 2 additional slow working ranges perfect for bedded crops.

See the PTO functional area for more information on E-PTO.

Specs & Compare

Key Specs | 5120ML Current Model |

| Engine description | OOS: John Deere PowerTech™ 4045 PWL Cab: John Deere PowerTech™ 4045 PWS |

| Engine displacement | 4 cylinders: 4.5 L 276 cu in. |

| Rated engine power | At 2200 rpm: 92 kW 120 hp |

| Maximum engine power | 92 kW 125 hp |

| Rated PTO power (hp SAE) | At 2100 rpm: 77.2 kW 105 hp |

| Maximum PTO power | |

| Transmission type | OOS: Standard: PowrReverser™ 16F/16R Optional: PowrQuad™ PLUS 16F/16R Powr8™ 32F/16R Cab: Standard: PowrQuad™ PLUS 16F/16R Optional: Powr8™ 32F/16R with creeper |

| Hydraulic pump rated output | OOS: Standard: 94 L/min 24.7 gpm Optional: 117 L/min 31 gpm Cab: 117 L/min 31 gpm |

| Rear hitch category (SAE designation) | Category 2 |

| Base machine weight | |

| Maximum engine power PS (hp ISO) at max engine speed (EU 2016/1628) | |

| Rated engine power PS (hp ISO) at rated engine speed (EU 2016/1628) | |

Engine specifications | |

| Description | OOS: John Deere PowerTech™ 4045 PWL Cab: John Deere PowerTech™ 4045 PWS |

| Engine type | 4045HLV81 |

| Engine family | NJDXL06.8309 |

| Rated speed | 2200 rpm |

| Aspiration | Turbocharged |

| Cylinders liners | Wet sleeved |

| Emission level | Final Tier 4 |

| After treatment type | OOS: ERG/DOC/SCR Cab: EGR/DOC/DPF/SC |

| Displacement | 4 cylinders: 4.5 L 276 cu in. |

Engine performance | |

| Rated power | At 2200 rpm: 92 kW 120 hp |

| Rated PTO power (hp SAE) | At 2100 rpm: 77.2 kW 105 hp |

| Maximum PTO power | |

| Intelligent Power Management (IPM) | |

| Power boost | At 1900 rpm: 4 percent |

| Maximum engine power | 92 kW 125 hp |

| Engine peak torque | At 1600 rpm: 500 Nm 369 lb-ft |

| Drawbar power | |

| PTO torque rise | At 1600 rpm: 30 percent |

| Fuel injection system and control | |

| Air cleaner type | |

| Maximum engine power PS (hp ISO) at max engine speed (EU 2016/1628) | |

| Rated engine power PS (hp ISO) at rated engine speed (EU 2016/1628) | |

Transmission | |

| Type | OOS: Standard: PowrReverser™ 16F/16R Optional: PowrQuad™ PLUS 16F/16R Powr8™ 32F/16R Cab: Standard: PowrQuad™ PLUS 16F/16R Optional: Powr8™ 32F/16R with creeper |

| Reverser | Yes |

| Clutch; wet/dry | Wet |

| Creeper | Cab: Powr8™ 32F/16R with creeper |

Hydraulic system | |

| Type | OOS: Standard: Open center Optional: Pressure-and-flow compensated (PFC) system Cab: Pressure-and-flow compensated (PFC) system |

| Pump rated output | OOS: Standard: 94 L/min 24.7 gpm Optional: 117 L/min 31 gpm Cab: 117 L/min 31 gpm |

| Available flow at a single rear SCV | OOS: Standard: 70 L/min 18.4 gpm Optional: 100 L/min 26.4 gpm Cab: 100 L/min 26.4 gpm |

| Available flow at front SCVs | |

| Number of rear selective control valves (SCVs) | Three |

| Number of mid selective control valves (SCVs) | Standard: Zero Optional: Up to Three |

| Number of front selective control valves (SCVs) | |

| Joystick SCV control | OOS: Mechanical Cab: Rear SCVs: Mechanical Mid-SCVs: Electrohydraulic |

| Auxiliary hydraulic features | |

| SCV control | |

Rear hitch | |

| Hitch draft control load sense type | OOS: Standard: Mechanical Optional: Electrohydraulic Cab: Electrohydraulic |

| Remote control valves available | Three |

| Hitch category (SAE designation) | Category 2; convertible to 1 |

| Maximum lift capacity behind lift points | OOS: Standard for PowrReverser™: 2223 kg 4900 lb Optional for PowrReverser™: 2565 kg 5654 lb Optional for PowrQuad™ PLUS/Powr8™: 3164 kg 6975 lb Optional for PowrQuad™ PLUS/Powr8™: 3569 kg 7868 lb Cab: Standard: 2720 kg 5996 lb Optional: 3122 kg 6883 lb |

| Lift capacity at standard frame | |

| Sensing type | Top link |

| Rear axle differential lock | Electrohydraulic |

Drawbar | |

| Drawbar category | Category 2 |

| Maximum vertical load | Road/field use (250-mm extended): 1450 kg 3197 lb Field use (350-mm extended): 1200 kg 2646 lb Field use (400-mm extended): 1200 kg 2646 lb |

Rear power take-off (PTO) | |

| Type | OOS: Standard: 540/540E Optional: 540/540E/1000 Cab: Standard: 540/540E/1000 |

| Engine rpm (at rated PTO speeds) | 540 at 2100 rpm 540E at 1645 rpm 1000 at 2100 rpm |

| Economy PTO speeds | |

| Reverse PTO speeds | |

| Multispeed PTO option availability | |

| Ground speed PTO option availability | |

| PTO actuation | Electrohydraulic |

Front hitch | |

| Category | Cab: Category 2 |

| Electric power | |

| Standard lift capacity | Cab: 1780 kg (3924 lbs) |

| Front power take-off (PTO) | Cab: 1000 rpm (21 spline) 34.9 mm (1.375 in.) |

| PTO speed | Cab: 1000 at 2200 rpm |

Rear axle | |

| Type | Flange |

| Final drive type | Inboard planetary |

| Differential controls | Electrohydraulic |

| Axle type | |

| Brakes, type and control | Hydraulic wet disc |

| Rear differential lock | |

| Load rating | |

Front axle | |

| Type | Mechanical Front Wheel Drive (MFWD) |

| Front axle differential lock | |

| Load rating | |

Tires | |

| Rear | 19.5L - 24 in. 10PR R4 Bias |

| Wheel tread range | Front: 1299-1997 mm 51.1-78.6 in. |

| Turning radius with brakes | 3.34 m 11.0 ft |

| Turning radius without brakes | 3.8 m 12.5 ft |

| Central Tire Inflation System (CTIS) | |

| Front | |

Tracks | |

| Tread spacing | |

| Drive type | |

| Track width | |

| Mid-rollers | |

Steering | |

| Type | |

Brakes | |

| Primary brake (foot brake) | |

| Secondary brake | Cab: Yes, when equipped with Hydraulic trailer brakes |

| Park lock | |

| MFWD braking | |

| Front axle brakes | |

| Auxiliary brakes | |

| Hydraulic trailer brakes | Cab: Optional |

| Pneumatic trailer brakes | |

Electrical system | |

| Alternator size | OOS: 90 amp Cab: 120 amp ISOBUS/GreenStar™ Ready: 200 amp |

| Battery options | 12 V |

| Working lights | Standard: Halogen Optional: LED |

| Type of bulb in headlight (Halogen, Zenon, LED) | Standard: Halogen Optional: LED |

| Type of bulb in beacon (Halogen, Zenon, LED) | Kit: LED |

| dB(A) rating for backup alarm | |

| Total cold cranking amps | |

Operator station | |

| Rollover protective structure, OOS | Rigid - foldable - telescopic Foldable, two-post Platform - flat/straddle Flat Gearshift location - console/floor Floor |

| Seat | OOS: Low Profile Cab: Air Ride |

| Cab suspension | |

| Instructional seat | Not Available |

| Display | OOS: Automotive style light-emitting LED instrument cluster Cab: Digital Dash Display with three liquid crystal displays (LCDs) |

| Radio | Optional |

| Inner cab volume | 55 cu ft |

| dB(A) rating | 80 dBA |

| Cab glass area | |

| Safety glass rating | Tempered per SAE J673 and ECE R43-01 requirements |

| Front visibility | |

Dimensions | |

| Wheelbase | OOS: 2350 mm 92.5 in. Cab: MFWD Standard: 2350 mm MFWD Narrow: 2300 mm 90.5 in. |

| Overall width | |

| Overall length | OOS: 4092 mm 161 in. Cab: MFWD Standard: 4000 mm 157.7 in. MFWD Narrow: 3945 mm 155 in. |

| Overall height | |

| Drawbar clearance | |

| Front axle center | |

| Approximate shipping weight, Open;Cab | Open: PowrReverser™ : 3964 kg 8740 lb Open: PowrQuad™ PLUS/Powr8™: 4209 kg 9280 lb Cab: 4826 kg 10640 lb |

Weight | |

| Base machine weight | |

| Maximum ballast level | |

| Maximum permissible weight | |

Capacities | |

| Crankcase oil volume | |

| Fuel tank | Standard for PowrReverser™: 112 L 29.6 U.S. gal. Standard for PowrQuad™ PLUS/Powr8™ models: 144 L 38 U.S. gal. |

| Diesel exhaust fluid (DEF) tank | 12 L 3.17 U.S. gal. |

| Cooling system | |

| Transmission-hydraulic system | |

Serviceability | |

| Interval for engine oil change | |

| Interval for hydraulic/transmission oil change | |

| Interval for engine coolant change | |

Loaders | |

| Loader | |

| Lift capacity at full height | |

| Maximum lift height | |

| Leveling type | |

Precision AG | |

| Guidance | Optional: AutoTrac™ with AutoTrac Basic |

| Telematic | JDLink™ Modem |

| Remote diagnostics | Yes |

Miscellaneous | |

| AutoTrac ready | Optional for cab models |

| ISOBUS ready | Optional for cab models |

| CommandCenter video inputs | |

| Immobilizer | |

| Side slope rating | |

| Uphill/downhill slope rating | |

| Country of manufacture | Saltillo, Mexico |

Additional information | |

| Date collected | 6-Jan-2023 |

Offers & Discounts

Accessories & Attachments

Hydraulics

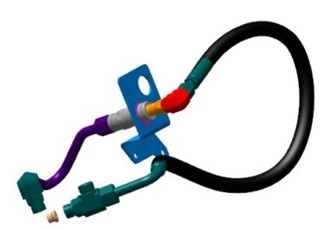

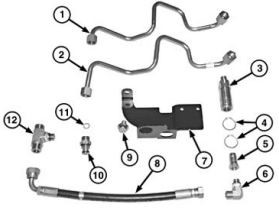

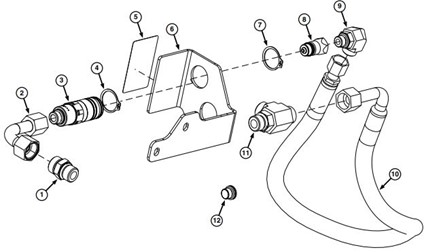

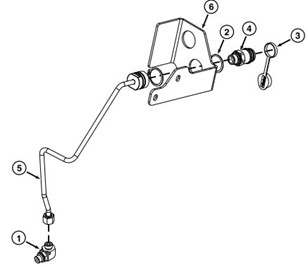

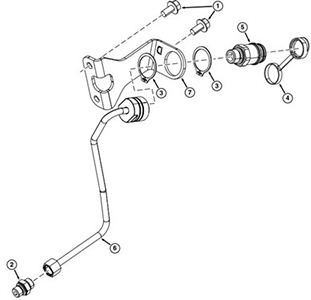

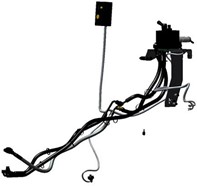

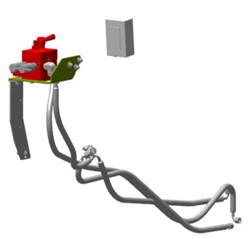

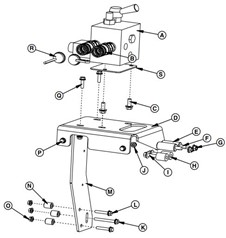

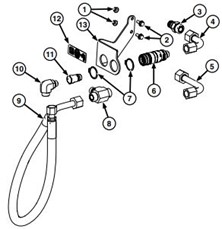

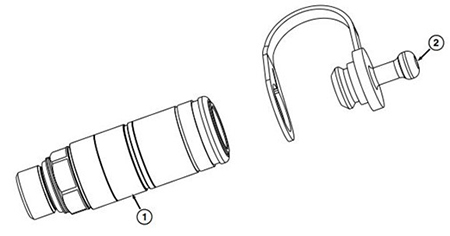

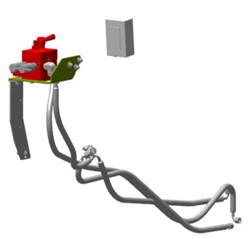

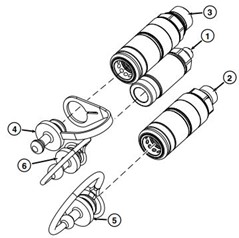

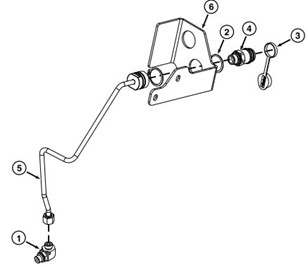

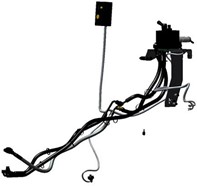

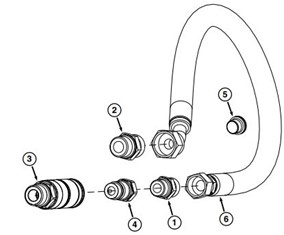

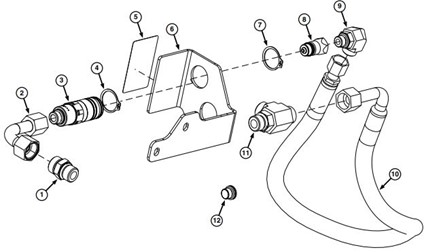

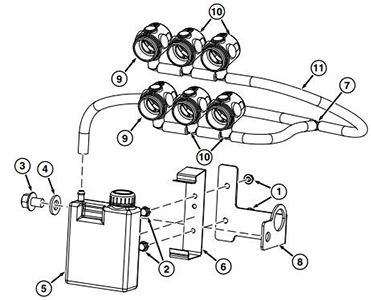

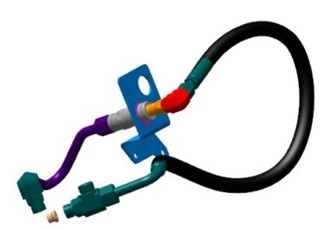

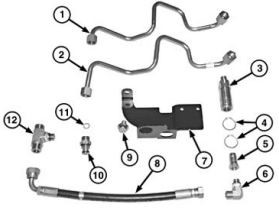

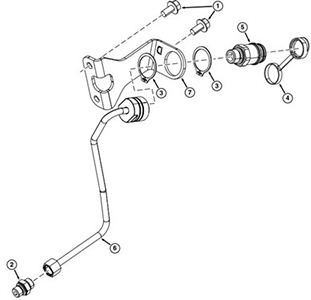

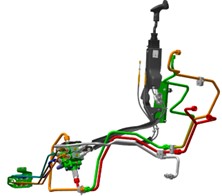

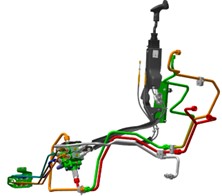

BSJ10345 motor control kit shown

BSJ10345 motor control kit shown

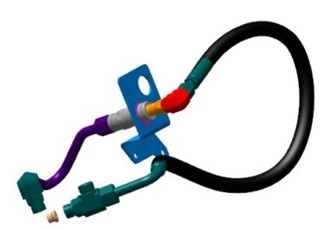

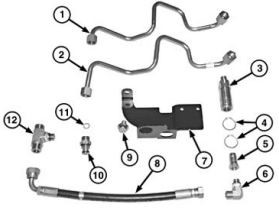

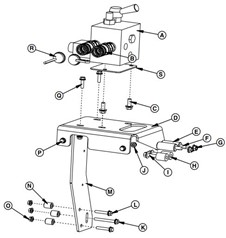

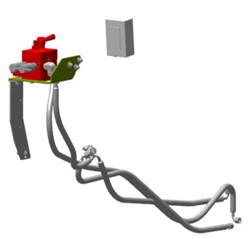

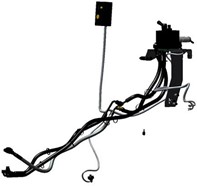

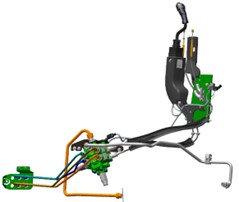

RE282528 Motor Control Kit shown

RE282528 Motor Control Kit shown

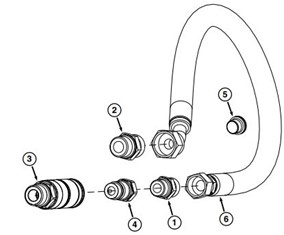

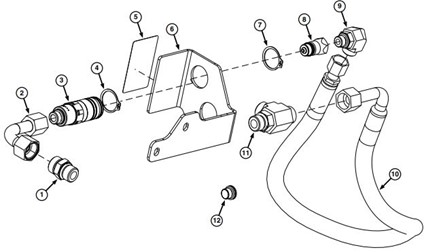

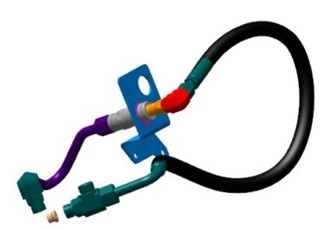

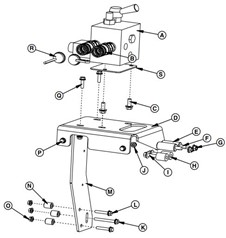

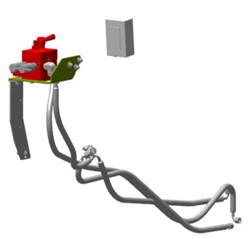

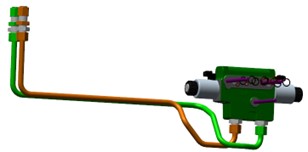

BXX10688 Motor Control Kit shown

BXX10688 Motor Control Kit shown

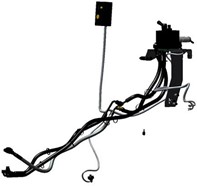

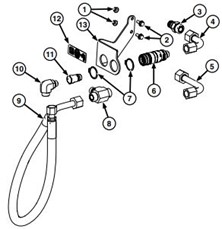

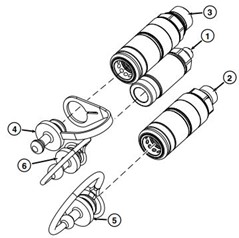

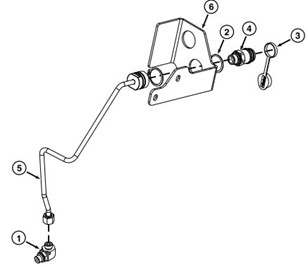

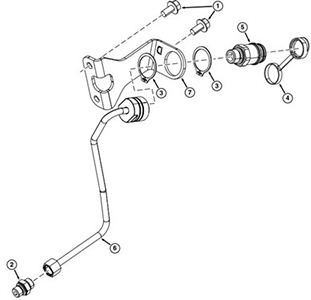

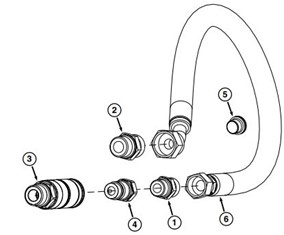

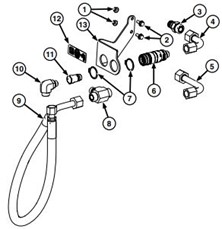

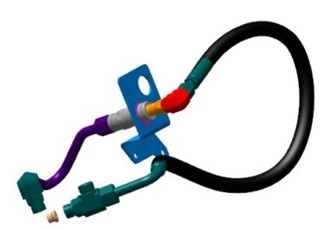

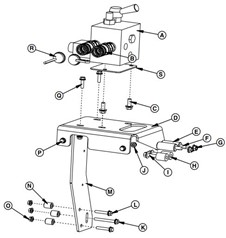

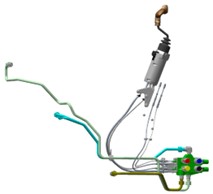

RE193598 Power Beyond Kit shown

RE193598 Power Beyond Kit shown

RE182800 Motor Control Kit shown

RE182800 Motor Control Kit shown

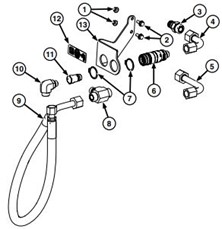

BSJ10282 Power Beyond Kit shown

BSJ10282 Power Beyond Kit shown

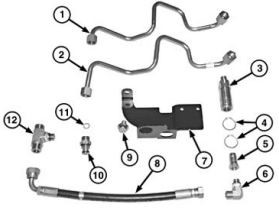

BSJ10194 Power Beyond Kit shown

BSJ10194 Power Beyond Kit shown

BSJ10241 Power Beyond Kit shown

BSJ10241 Power Beyond Kit shown

BSJ10240 Power Beyond Kit shown

BSJ10240 Power Beyond Kit shown

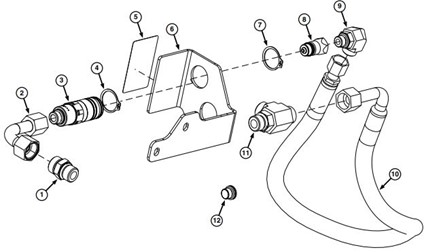

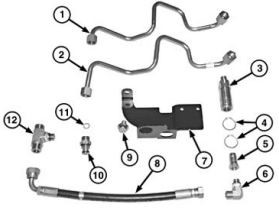

BLV10416 Power Beyond Kit shown

BLV10416 Power Beyond Kit shown

R228089 Power Beyond Kit shown

R228089 Power Beyond Kit shown

RE242111 Power Beyond Kit shown

RE242111 Power Beyond Kit shown

BSJ10091 Power Beyond Kit shown

BSJ10091 Power Beyond Kit shown

BSJ10092 Hydraulic Motor Case Drain and Motor Return Kit shown

BSJ10092 Hydraulic Motor Case Drain and Motor Return Kit shown

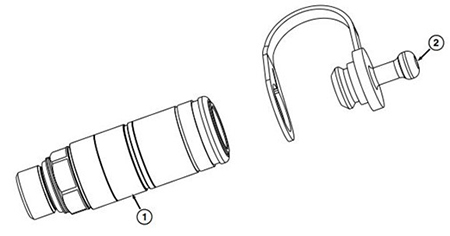

BSJ10243 Motor Return Coupler Kit shown

BSJ10243 Motor Return Coupler Kit shown

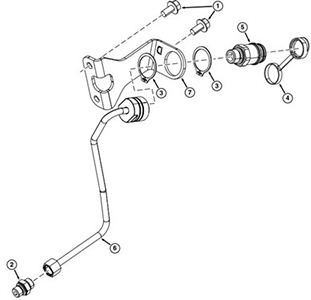

BSJ10428 Motor Case Drain Kit shown

BSJ10428 Motor Case Drain Kit shown

BSJ10465 Rear SCV Oil Collection Kit shown

BSJ10465 Rear SCV Oil Collection Kit shown

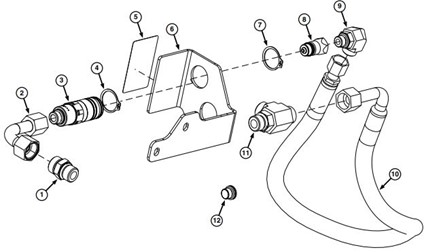

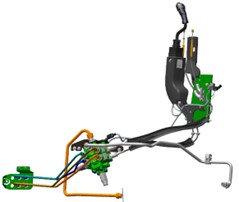

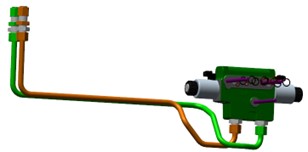

Overview

Adjust the continuous flow rate of the hydraulic fluid to the rear of the tractor with the motor control kit or get continuous flow with power beyond kits.

Benefits

- Allows for hydraulic flow rate adjustments

- Routes hydraulic flow to the rear of the tractor

- Enables the operator to run implements and attachments requiring continuous flow such as a hydraulic motor

- NOTE - A Power Beyond kit is NOT needed on any 5E 3-Cylinder tractors, as the hydraulic system design does not necessitate a power beyond kit.

BSJ10345 motor control kit shown

BSJ10345 motor control kit shown

RE282528 Motor Control Kit shown

RE282528 Motor Control Kit shown

BXX10688 Motor Control Kit shown

BXX10688 Motor Control Kit shown

RE193598 Power Beyond Kit shown

RE193598 Power Beyond Kit shown

RE182800 Motor Control Kit shown

RE182800 Motor Control Kit shown

BSJ10282 Power Beyond Kit shown

BSJ10282 Power Beyond Kit shown

BSJ10194 Power Beyond Kit shown

BSJ10194 Power Beyond Kit shown

BSJ10241 Power Beyond Kit shown

BSJ10241 Power Beyond Kit shown

BSJ10240 Power Beyond Kit shown

BSJ10240 Power Beyond Kit shown

BLV10416 Power Beyond Kit shown

BLV10416 Power Beyond Kit shown

R228089 Power Beyond Kit shown

R228089 Power Beyond Kit shown

RE242111 Power Beyond Kit shown

RE242111 Power Beyond Kit shown

BSJ10091 Power Beyond Kit shown

BSJ10091 Power Beyond Kit shown

BSJ10092 Hydraulic Motor Case Drain and Motor Return Kit shown

BSJ10092 Hydraulic Motor Case Drain and Motor Return Kit shown

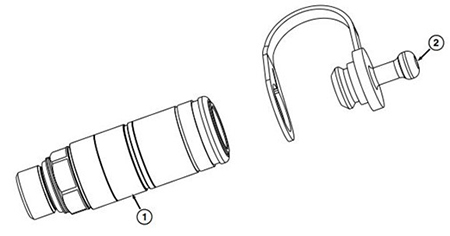

BSJ10243 Motor Return Coupler Kit shown

BSJ10243 Motor Return Coupler Kit shown

BSJ10428 Motor Case Drain Kit shown

BSJ10428 Motor Case Drain Kit shown

BSJ10465 Rear SCV Oil Collection Kit shown

BSJ10465 Rear SCV Oil Collection Kit shown

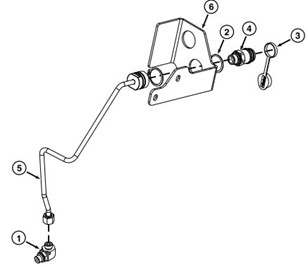

Overview

Adjust the continuous flow rate of the hydraulic fluid to the rear of the tractor with the motor control kit or get continuous flow with power beyond kits.

Benefits

- Allows for hydraulic flow rate adjustments

- Routes hydraulic flow to the rear of the tractor

- Enables the operator to run implements and attachments requiring continuous flow such as a hydraulic motor

- NOTE - A Power Beyond kit is NOT needed on any 5E 3-Cylinder tractors, as the hydraulic system design does not necessitate a power beyond kit.

BSJ10345 motor control kit shown

BSJ10345 motor control kit shown

RE282528 Motor Control Kit shown

RE282528 Motor Control Kit shown

BXX10688 Motor Control Kit shown

BXX10688 Motor Control Kit shown

RE193598 Power Beyond Kit shown

RE193598 Power Beyond Kit shown

RE182800 Motor Control Kit shown

RE182800 Motor Control Kit shown

BSJ10282 Power Beyond Kit shown

BSJ10282 Power Beyond Kit shown

BSJ10194 Power Beyond Kit shown

BSJ10194 Power Beyond Kit shown

BSJ10241 Power Beyond Kit shown

BSJ10241 Power Beyond Kit shown

BSJ10240 Power Beyond Kit shown

BSJ10240 Power Beyond Kit shown

BLV10416 Power Beyond Kit shown

BLV10416 Power Beyond Kit shown

R228089 Power Beyond Kit shown

R228089 Power Beyond Kit shown

RE242111 Power Beyond Kit shown

RE242111 Power Beyond Kit shown

BSJ10091 Power Beyond Kit shown

BSJ10091 Power Beyond Kit shown

BSJ10092 Hydraulic Motor Case Drain and Motor Return Kit shown

BSJ10092 Hydraulic Motor Case Drain and Motor Return Kit shown

BSJ10243 Motor Return Coupler Kit shown

BSJ10243 Motor Return Coupler Kit shown

BSJ10428 Motor Case Drain Kit shown

BSJ10428 Motor Case Drain Kit shown

BSJ10465 Rear SCV Oil Collection Kit shown

BSJ10465 Rear SCV Oil Collection Kit shown

Overview

Adjust the continuous flow rate of the hydraulic fluid to the rear of the tractor with the motor control kit or get continuous flow with power beyond kits.

Benefits

- Allows for hydraulic flow rate adjustments

- Routes hydraulic flow to the rear of the tractor

- Enables the operator to run implements and attachments requiring continuous flow such as a hydraulic motor

- NOTE - A Power Beyond kit is NOT needed on any 5E 3-Cylinder tractors, as the hydraulic system design does not necessitate a power beyond kit.

BSJ10345 motor control kit shown

BSJ10345 motor control kit shown

RE282528 Motor Control Kit shown

RE282528 Motor Control Kit shown

BXX10688 Motor Control Kit shown

BXX10688 Motor Control Kit shown

RE193598 Power Beyond Kit shown

RE193598 Power Beyond Kit shown

RE182800 Motor Control Kit shown

RE182800 Motor Control Kit shown

BSJ10282 Power Beyond Kit shown

BSJ10282 Power Beyond Kit shown

BSJ10194 Power Beyond Kit shown

BSJ10194 Power Beyond Kit shown

BSJ10241 Power Beyond Kit shown

BSJ10241 Power Beyond Kit shown

BSJ10240 Power Beyond Kit shown

BSJ10240 Power Beyond Kit shown

BLV10416 Power Beyond Kit shown

BLV10416 Power Beyond Kit shown

R228089 Power Beyond Kit shown

R228089 Power Beyond Kit shown

RE242111 Power Beyond Kit shown

RE242111 Power Beyond Kit shown

BSJ10091 Power Beyond Kit shown

BSJ10091 Power Beyond Kit shown

BSJ10092 Hydraulic Motor Case Drain and Motor Return Kit shown

BSJ10092 Hydraulic Motor Case Drain and Motor Return Kit shown

BSJ10243 Motor Return Coupler Kit shown

BSJ10243 Motor Return Coupler Kit shown

BSJ10428 Motor Case Drain Kit shown

BSJ10428 Motor Case Drain Kit shown

BSJ10465 Rear SCV Oil Collection Kit shown

BSJ10465 Rear SCV Oil Collection Kit shown

Overview

Adjust the continuous flow rate of the hydraulic fluid to the rear of the tractor with the motor control kit or get continuous flow with power beyond kits.

Benefits

- Allows for hydraulic flow rate adjustments

- Routes hydraulic flow to the rear of the tractor

- Enables the operator to run implements and attachments requiring continuous flow such as a hydraulic motor

- NOTE - A Power Beyond kit is NOT needed on any 5E 3-Cylinder tractors, as the hydraulic system design does not necessitate a power beyond kit.

BSJ10345 motor control kit shown

BSJ10345 motor control kit shown

RE282528 Motor Control Kit shown

RE282528 Motor Control Kit shown

BXX10688 Motor Control Kit shown

BXX10688 Motor Control Kit shown

RE193598 Power Beyond Kit shown

RE193598 Power Beyond Kit shown

RE182800 Motor Control Kit shown

RE182800 Motor Control Kit shown

BSJ10282 Power Beyond Kit shown

BSJ10282 Power Beyond Kit shown

BSJ10194 Power Beyond Kit shown

BSJ10194 Power Beyond Kit shown

BSJ10241 Power Beyond Kit shown

BSJ10241 Power Beyond Kit shown

BSJ10240 Power Beyond Kit shown

BSJ10240 Power Beyond Kit shown

BLV10416 Power Beyond Kit shown

BLV10416 Power Beyond Kit shown

R228089 Power Beyond Kit shown

R228089 Power Beyond Kit shown

RE242111 Power Beyond Kit shown

RE242111 Power Beyond Kit shown

BSJ10091 Power Beyond Kit shown

BSJ10091 Power Beyond Kit shown

BSJ10092 Hydraulic Motor Case Drain and Motor Return Kit shown

BSJ10092 Hydraulic Motor Case Drain and Motor Return Kit shown

BSJ10243 Motor Return Coupler Kit shown

BSJ10243 Motor Return Coupler Kit shown

BSJ10428 Motor Case Drain Kit shown

BSJ10428 Motor Case Drain Kit shown

BSJ10465 Rear SCV Oil Collection Kit shown

BSJ10465 Rear SCV Oil Collection Kit shown

Overview

Adjust the continuous flow rate of the hydraulic fluid to the rear of the tractor with the motor control kit or get continuous flow with power beyond kits.

Benefits

- Allows for hydraulic flow rate adjustments

- Routes hydraulic flow to the rear of the tractor

- Enables the operator to run implements and attachments requiring continuous flow such as a hydraulic motor

- NOTE - A Power Beyond kit is NOT needed on any 5E 3-Cylinder tractors, as the hydraulic system design does not necessitate a power beyond kit.

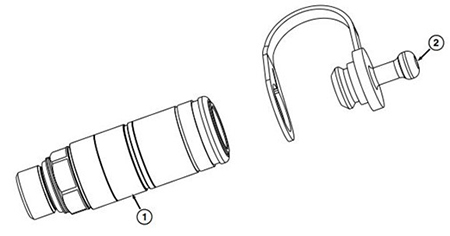

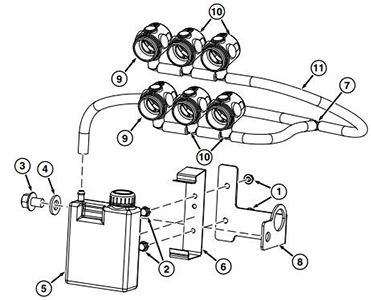

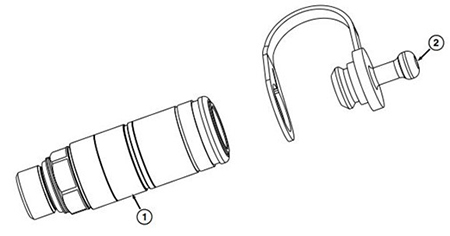

Mid Selective Control Valves

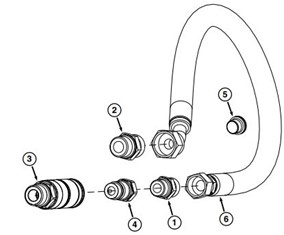

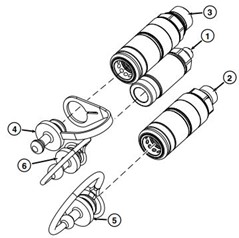

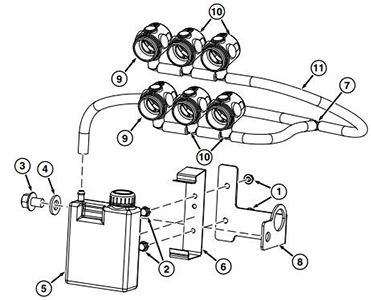

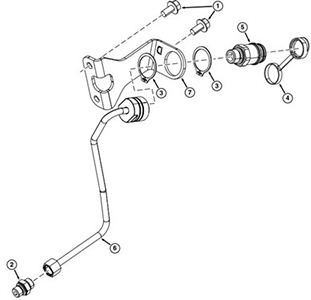

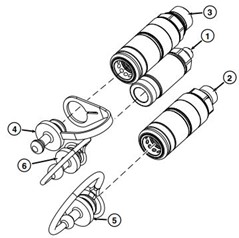

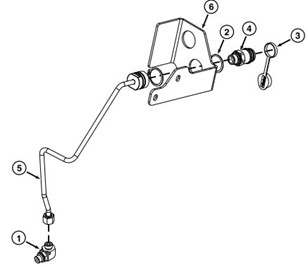

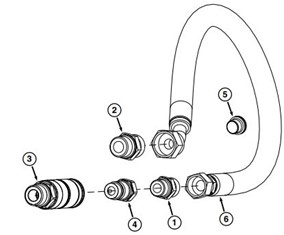

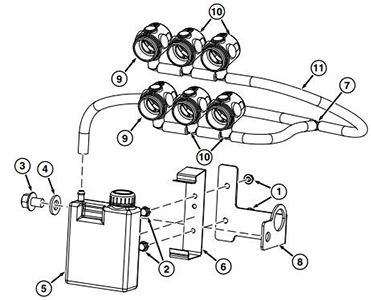

SJ13783 Mid-Coupler Kit shown

SJ13783 Mid-Coupler Kit shown

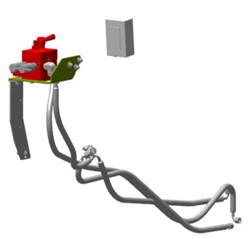

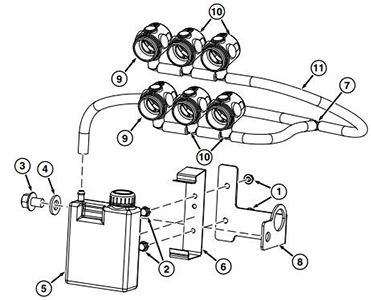

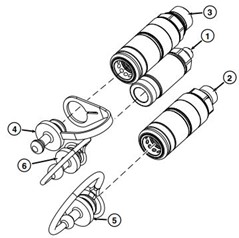

SJ17815 Dual Mid-Mount SCV Kit shown

SJ17815 Dual Mid-Mount SCV Kit shown

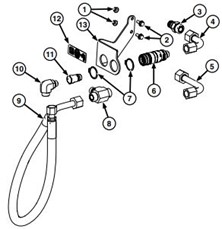

BSJ10101 Dual Mid to Triple SCV Kit shown

BSJ10101 Dual Mid to Triple SCV Kit shown

BSJ10227 Dual Mid to Triple SCV Kit shown

BSJ10227 Dual Mid to Triple SCV Kit shown

BSJ10228 Dual Mid SCV Kit shown

BSJ10228 Dual Mid SCV Kit shown

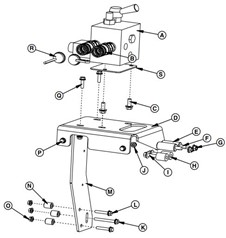

BSJ10330 Mechanical Mid SCV Kit shown

BSJ10330 Mechanical Mid SCV Kit shown

BSJ10333 Mechanical Mid SCV kit shown

BSJ10333 Mechanical Mid SCV kit shown

BSJ10472 2 to 3 Mid SCV Kit shown

BSJ10472 2 to 3 Mid SCV Kit shown

Overview

Provide hydraulic control to any front mounted implements with the John Deere Mid-Mounted SCV kits.

SJ13783 Mid-Coupler Kit shown

SJ13783 Mid-Coupler Kit shown

SJ17815 Dual Mid-Mount SCV Kit shown

SJ17815 Dual Mid-Mount SCV Kit shown

BSJ10101 Dual Mid to Triple SCV Kit shown

BSJ10101 Dual Mid to Triple SCV Kit shown

BSJ10227 Dual Mid to Triple SCV Kit shown

BSJ10227 Dual Mid to Triple SCV Kit shown

BSJ10228 Dual Mid SCV Kit shown

BSJ10228 Dual Mid SCV Kit shown

BSJ10330 Mechanical Mid SCV Kit shown

BSJ10330 Mechanical Mid SCV Kit shown

BSJ10333 Mechanical Mid SCV kit shown

BSJ10333 Mechanical Mid SCV kit shown

BSJ10472 2 to 3 Mid SCV Kit shown

BSJ10472 2 to 3 Mid SCV Kit shown

Overview

Provide hydraulic control to any front mounted implements with the John Deere Mid-Mounted SCV kits.