7R 310

Tractor

- Engine HP1: 341 Max | 310 hp Rated

- Fully integrated precision ag technology

- Choice of e23™ PowerShift or Infinitely Variable Transmission (IVT™)

- Three cab and visibility packages available to customize your tractor

- Industry-leading power transfer with Cat 4 HD drawbar for heavier implements

1Engine power PS (hp ISO) at max engine power speed (ECE-R120). John Deere Standard RES10080, SAE Standards J1995.

- Engine HP1: 341 Max | 310 hp Rated

- Fully integrated precision ag technology

- Choice of e23™ PowerShift or Infinitely Variable Transmission (IVT™)

- Three cab and visibility packages available to customize your tractor

- Industry-leading power transfer with Cat 4 HD drawbar for heavier implements

1Engine power PS (hp ISO) at max engine power speed (ECE-R120). John Deere Standard RES10080, SAE Standards J1995.

- Engine HP1: 341 Max | 310 hp Rated

- Fully integrated precision ag technology

- Choice of e23™ PowerShift or Infinitely Variable Transmission (IVT™)

- Three cab and visibility packages available to customize your tractor

- Industry-leading power transfer with Cat 4 HD drawbar for heavier implements

1Engine power PS (hp ISO) at max engine power speed (ECE-R120). John Deere Standard RES10080, SAE Standards J1995.

- Engine HP1: 341 Max | 310 hp Rated

- Fully integrated precision ag technology

- Choice of e23™ PowerShift or Infinitely Variable Transmission (IVT™)

- Three cab and visibility packages available to customize your tractor

- Industry-leading power transfer with Cat 4 HD drawbar for heavier implements

1Engine power PS (hp ISO) at max engine power speed (ECE-R120). John Deere Standard RES10080, SAE Standards J1995.

Features

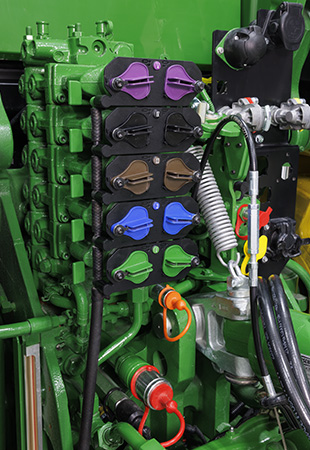

SCV stack

SCV stack

Beginning with model year 2024, 7, 8 and 9 Series tractors will feature a new SCV stack to improve performance and aftermarket serviceability. The change will further enable customers to fine-tune hydraulic flow rates and more precisely adjust the flow. This change will make it easier and more affordable to customize an SCV stack by switching coupler sizes because previously it would’ve been done by changing an entire SCV slice.

7R driving on roadway

7R driving on roadway

Is your 7R tractor the “Road Warrior” of your operation? If so, then Reactive Steering is for you. Adopted from the automotive industry, Reactive Steering brings a balanced feeling to the steering wheel much like your automobile.

The load-reactive steering valve uses hydraulic inputs from both the left and right steering cylinders. When pressures increase on one side (during a turn, for instance) the valve provides feedback to the steering wheel to help assist the steering wheel back to center.

On straightaways, Reactive Steering reduces hand movements by helping the operator to maintain a center line. During internal testing, hand movements are reduced by as much as 44 percent during straight line driving.

Do you find it challenging to navigate roundabouts, intersections, or curvy back roads? Then Reactive Steering is a game changer. As you rotate the steering wheel to complete your turn, simply relax your grip on the wheel and notice how the steering wheel of your 7R returns to center.

7R performing transport work

7R performing transport work

Relieve the stress from transport jobs like towing tankers, trailers, and dump wagons for long hours. Reactive steering provides a balanced, automotive feeling to your 7R. Have confidence that your operators can perform transport jobs day after day with less fatigue.

Taking your 7R off-road? No problem. Reactive Steering works great in the field too. However, if you prefer to operate with traditional steering, a toggle button on the display puts the steering mode into traditional hydraulic steering for that familiar feel in the field. Operators always have the option to enable or disable Reactive Steering from the display.

Reactive Steering page

Reactive Steering page

AutoTrac™ Integration

Reactive Steering is not available while AutoTrac is engaged.

When an operator engages AutoTrac, Reactive Steering is automatically disabled. Once AutoTrac is disengaged, the steering mode will resume the previous state that was selected by the operator.

In addition, Reactive Steering is disabled when the tractor is placed into reverse. Once the tractor is placed into forward direction, the steering mode will resume the previous state that was selected by the operator.

Ultimate Comfort and Convenience package

Ultimate Comfort and Convenience package

The Ultimate Comfort and Convenience package offers unsurpassed visibility, operator comfort, control placement, and ride and sound quality. Features in this package include:

Controls

- CommandARM™ console with hitch and hydraulic integrated controls

- Air conditioner and heater with automatic temperature controls

- Radio and volume controls

- Hitch control lever lock and selective control lever lock

- Tilt/telescoping steering wheel with position memory

- Auto trac resume button

- iTEC™ engagement buttons

Displays

- G5Plus Display (for more information on the G5Plus, please see the Precision Ag Technology Sales Manual and Extended Monitor option

- Digital cornerpost display with:

- Fuel level gauge, including low fuel warning

- Temperature gauge

- Diesel exhaust fluid (DEF) gauge, including low DEF warning

- Engine rpm

- Transmission commanded gear or wheel speed

- Vehicle system functions, such as iTEC system, that are operating

- Monitor mounts on right-hand front post and rear cab post

Storage

- Storage compartment underneath the instructor seat

- Left-hand ceiling storage compartment

- Refrigerator located on the left side behind the instructor seat

- Beverage holders sized to accommodate various containers

Sound

- Passive noise reduction system

- Premium sound system, including touchscreen radio, smartphone interface, AM/FM/WX, aux and Bluetooth® wireless with voice control, inputs, XM® ready, six speakers with one subwoofer, and business band ready

Outlets

- Three 12-V convenience outlets (cigarette lighter style)

- Six 12-V three-pin outlets with adapter (provides switched and unswitched power)

- Four charging USB ports (two USB-A and two USB- C)

- 120-V AC power outlet

- One International Organization for Standardization (ISO) nine-pin connector

- Service ADVISOR™ data port

Windows

- Swing-out rear window that opens 30 degrees

- Laminated glass with optional rear window tint

- Two-speed and intermittent front, rear, and right-hand side wiper with washer

- Front, left and right-hand side, and rear pull-down sunshade

Lights

- Interior dome light in the ceiling

- Map lights

For additional attachments and mounting solutions, see Cab convenience or Cab mounting solutions.

Seat

Leather seat

Leather seat

The seat improves ride quality and helps to reduce operator fatigue.

Features include:

- Leather

- Heat and ventilation to keep the operator at a comfortable temperature

- Adjustable bolsters

- Massage functionality

- Electronic controls to adjust to operator preference

- Pneumatic lumbar adjustment

- Seat height adjustments conveniently located below the left armrest

- Fore-aft adjustment is easy to reach, located below the left armrest

- Swivel adjustment, located on the front of the seat, allows the seat to be swiveled 40 degrees to the right or 25 degrees to the left of the center position with a pivoting CommandARM console

- Seat can be configured with air seat suspension, ActiveSeat™ II suspension, or air seat plus cab suspension

- Operator presence switch warns if the operator is out of the seat while operating key functions

- Seat belt retractor

- Centered cab seat provides excellent over-shoulder visibility

- Adjustable shock absorber permits ride adjustment from soft to firm to match the operator's desired comfort level

- Removable cushions allow for easy cleaning

- Folding instructional seat

Bluetooth is a trademark of Bluetooth SIG, Inc. XM is a trademark of Sirius XM Radio, Inc.

Visibility package (without rear window tint)

Visibility package (without rear window tint)

Visibility package (with rear window tint*)

Visibility package (with rear window tint*)

Visibility is more than just lighting. It’s mirrors where you need them, shades for the blinding late-fall and early-spring sun, wipers to help keep all the glass clear, and integrated camera capability. The 7 and 8 Series Tractors let you choose the visibility package that best suits your needs – Select, Premium, or Ultimate with 360-degree light-emitting diode (LED) lighting –so you and your operators can run with all-conditions confidence.

| Visibility packages | Select | Premium | Ultimate |

| Lighting | 18 halogen work lights | 18 LED work lights | 22 LED work lights and eight LED convenience lights** |

| Mirrors | Mechanical | Electric, heated | Electric, heated, and telescoping |

| Sunshades | Front | Front, right-hand side, and rear | Front, right-hand side, and rear |

| Wipers | Front and rear | Front, right-hand side, and rear | Front, right-hand side, and rear |

| Cameras | Camera ready | Camera ready | Integrated digital cameras |

*Rear window tint: À la carte option for all cab packages

**Convenience lights illuminate the corners of the cab for easier entry and exit

CommandARM™ console with CommandPRO control

CommandARM™ console with CommandPRO control

The unique driving strategy is designed to deliver highest performance in combination with operator comfort making the daily work much easier and efficient.

Driving strategy

- Pedal and joystick mode are active at the same time

- ActiveZero keeps the output speed actively at 0 km/h (0 mph) until command for acceleration is given independent of load or engine speed

- Command top and zero speed simply by one push or pull

- Unique inching control

- Three easily adjustable travel set speeds

- Two engine set speeds

- Three acceleration response settings

Driving strategy

Driving strategy

| Forward movement | Reverse movement | |

| 1 | Accelerate | Decelerate |

| 2 | Top set speed | Zero speed |

| 3 | Decelerate | Accelerate |

| 4 | Zero speed | Accelerate |

| 5 | Activate set speed | |

| 6 | Select direction | |

| 7 | Inching speed | |

| 8 | Inching speed | |

NOTE: The CommandPRO control is only available on IVT™ transmissions.

7 Series with front hitch

7 Series with front hitch

The 7R Tractors offer two front hitch options to best fit a variety of applications.

Standard (non-ground-engaging) hitch option for applications including, but not limited to:

- Front-mounted mowers, toppers, and snow blowers

- Carrying front seed hoppers and plow packers

- Carrying front ballast

- Operating light-draft implements

Premium (ground-engaging) hitch option for applications including, but not limited to:

- Operating primary tillage equipment and standard blades

Premium hitches include a push bar and heavier lift arms:

- Hitches with zero front auxiliary valves include one mid-mount valve.

- Hitches with one front auxiliary valve include two mid-mount valves.

- Hitches with two front auxiliary valves include three mid-mount valves.

To ensure adequate hydraulic availability, up to two selective control valves (SCVs) can be included with a front hitch.

Joystick control

Joystick control

Paddle pot SCV

Paddle pot SCV

Tractors equipped with a factory front hitch have the option of selecting a joystick control or paddle pot SCV controls. The joystick control is not compatible with the sixth rear electrohydraulic SCV because of the CommandARM™ controls space required for the front hitch joystick.

Maximizing uptime using connectivity and technology

Maximizing uptime using connectivity and technology

Your needs and success are the focus of John Deere. John Deere makes it easy for you to benefit from having a connected tractor in your operation. All tractors come standard with JDLink™ telematics system and users can turn on connectivity in the John Deere Operations Center™ application. With a StarFire™ Integrated Receiver and G5Plus Display, you can easily step right into advanced technology. If you’re an advanced tech user, you’ll enjoy the benefits of a highly intelligent machine connected to a full suite of solutions on the most open platform in the industry. Advantages of a connected machine include:

- A StarFire Integrated Receiver eliminates all setup, installation, and global positioning system (GPS) calibrations

- AutoTrac™ assisted steering guides the machine with accuracy in a variety of field conditions

- Automation is an option with some applications

- John Deere Connected Support™ is a proactive service approach to improve service efficiency and reduce machine downtime

- JDLink gives you access to information anytime, anywhere, to make data driven decisions with John Deere Operations Center and Documentation

The technology and connectivity in John Deere tractors allow you to optimize productivity, increase uptime, and boost profits with machine information from any device, anywhere.

|

|

|

| Large tractor equipment | Precision Technology | JDLink |

Base equipment:

Optional equipment:

|

Base equipment:

Optional equipment*:

|

Base equipment:

|

*Available with G5 Advanced Tractor License, for more information on G5 Advanced Licenses please visit the Precision Ag Technology Guidance, Automation and Autonomy Sales Manual.

Specs & Compare

Key Specs | 7R 310 Current Model |

| Engine description | John Deere PowerTech™ (B20 diesel compatible) 9.0L |

| Engine displacement | 9.0 L 549 cu in. |

| Rated engine power | ECE-R120: 228 kW 310 hp |

| Maximum engine power | ECE-R120: 251 kW 341 hp |

| Rated PTO power (hp SAE) | 193.9 kW 260 hp |

| Maximum PTO power | |

| Transmission type | Standard: John Deere e23™ 42 km/h 26 mph Optional: John Deere e23 transmission 50 km/h 31 mph John Deere Infinitely Variable Transmission (IVT™) 0.050-42 km/h (0.030-26 mph) John Deere Infinitely Variable Transmission (IVT) 0.050-50 km/h (0.030- 31 mph) |

| Hydraulic pump rated output | Standard: 63 cc: 162 L/min 43 gpm Optional: 85 cc: 222.3 L/min 59 gpm |

| Rear hitch category (SAE designation) | Standard: Category 3N/3 with Quik-Coupler Optional: Category 3/3N with hook ends Category 3N/3 with hook ends |

| Base machine weight | e23, TLS™, 18.4R46: 10,000 kg 22,000 lb |

| Maximum engine power PS (hp ISO) at max engine speed (EU 2016/1628) | |

| Rated engine power PS (hp ISO) at rated engine speed (EU 2016/1628) | |

Engine specifications | |

| Description | John Deere PowerTech™ (B20 diesel compatible) 9.0L |

| Engine type | Diesel, in-line, 6-cylinder, wet-sleeve cylinder liners with 4 valves in head |

| Engine family | MJDXL09.0319 |

| Rated speed | 2100 rpm |

| Aspiration | Single turbocharger, variable geometry turbo |

| Cylinders liners | |

| Emission level | Final Tier 4 |

| After treatment type | Diesel oxidation catalyst (DOC)/diesel particulate filter (DPF) |

| Displacement | 9.0 L 549 cu in. |

Engine performance | |

| Rated power | ECE-R120: 228 kW 310 hp |

| Rated PTO power (hp SAE) | 193 kW 260 hp |

| Maximum PTO power | |

| Intelligent Power Management (IPM) | |

| Power boost | IPM: 22 kW 30 hp |

| Maximum engine power | ECE-R120: 251 kW 341 hp |

| Engine peak torque | At 1600 rpm: 1,452 Nm 1,071 lb-ft |

| Drawbar power | |

| PTO torque rise | 40 percent |

| Fuel injection system and control | |

| Air cleaner type | |

| Maximum engine power PS (hp ISO) at max engine speed (EU 2016/1628) | |

| Rated engine power PS (hp ISO) at rated engine speed (EU 2016/1628) | |

Transmission | |

| Type | Standard: John Deere e23™ 42 km/h 26 mph Optional: John Deere e23 transmission 50 K 31 mph John Deere Infinitely Variable Transmission (IVT™) 0.050-42 km/h (0.030-26 mph) John Deere Infinitely Variable Transmission (IVT) 0.050-50 km/h (0.030- 31 mph) |

| Reverser | |

| Clutch; wet/dry | |

| Creeper | |

Hydraulic system | |

| Type | Closed-center, pressure/flow compensated system with load sensing |

| Pump rated output | Standard: 63 cc: 162 L/min 43 gpm Optional: 85 cc: 222.3 L/min 59 gpm |

| Available flow at a single rear SCV | 132 L/min 35 gpm |

| Available flow at front SCVs | 126 L/min 33 gpm |

| Number of rear selective control valves (SCVs) | Standard: Four SCVs Optional: Three to six ISO couplers: 12.7 mm 1/2 in. Five ISO couplers (SCV 1: 19-mm [3/4-in.] couplers, SCV 2-5: 12.7-mm [1/2-in.] coupler) |

| Number of mid selective control valves (SCVs) | |

| Number of front selective control valves (SCVs) | One with front hitch |

| Joystick SCV control | |

| Auxiliary hydraulic features | |

| SCV control | Electronic |

Rear hitch | |

| Hitch draft control load sense type | |

| Remote control valves available | |

| Hitch category (SAE designation) | Standard: Category 3N/3 with Quik-Coupler Optional: Category 3/3N with hook ends Category 3N/3 with hook ends |

| Maximum lift capacity behind lift points | Standard (Category 3): 6,894 kg 15,200 lb Optional (Category 3N): 7,847 kg 17,300 lb Standard (Category 3 with hook ends): 6,894 kg Optional (Category 3N with hook ends): 7,847 kg |

| Lift capacity at standard frame | |

| Sensing type | Electrohydraulic |

| Rear axle differential lock | |

Drawbar | |

| Drawbar category | Standard: Category 4 |

| Maximum vertical load | Standard: Category 3: 1,837 kg 4,050 lb Optional: Category 3 with heavy-duty support: 4,536 kg 10,000 lb |

Rear power take-off (PTO) | |

| Type | Independent Standard: 44.45 mm (1.75 in.) 20-spline, 1,000 rpm Optional: 44.45 mm (1.75 in.), 20-spline, 1,000 rpm capable of 35 mm (1.375 in.) 540/1000 rpm 44.45 mm (1.75 in.) 20-spline, 1000 rpm with 35-mm (1.375-in.) 540E/1000/1000E rpm gearcase 44.45 mm (1.75 in.) 20-spline, 1000 rpm with 35-mm (1.375-in.) 540/540E/1000 rpm gearcase |

| Engine rpm (at rated PTO speeds) | 540/1000 PTO rpm at 1950 engine rpm 540E/1000E PTO rpm at 1750 engine rpm |

| Economy PTO speeds | |

| Reverse PTO speeds | |

| Multispeed PTO option availability | |

| Ground speed PTO option availability | |

| PTO actuation | Electric switch with adjustable modulation |

Front hitch | |

| Category | Category 3N, ground engaging |

| Electric power | Seven-pin connector |

| Standard lift capacity | 5,200 kg 11,464 lb |

| Front power take-off (PTO) | Available: 35 mm (1.375 in.) 21 spline, 1,000 rpm, counter-clockwise rotation (when facing PTO) Available through Parts: 44.45 mm (1.75 in.), 20 spline, 1,000 rpm, counter-clockwise rotation (when facing PTO) |

| PTO speed | 1,000 PTO rpm at 1940 engine rpm |

Rear axle | |

| Type | Standard: Rack-and-pinion or flange axles Optional: Diameter: 110 x 2550 mm 4.33 x 100.4 in. Diameter: 110 x 3010 mm 4.33 x 118.5 in. Diameter: 120 x 2550 mm 4.72 x 100.4 in. Diameter: 120 x 3010 mm 4.72 x 118.5 in. Flanged axle: 335 mm (13.2 in.) |

| Final drive type | Inboard planetary three pinion |

| Differential controls | |

| Axle type | |

| Brakes, type and control | |

| Rear differential lock | Full-locking electrohydraulic |

| Load rating | |

Front axle | |

| Type | Standard: 1300 Series MFWD: tread range 1524 to 2235 mm 60 to 88 in. Optional: TLS: Tread range 1524 to 2235 mm TLS with front brakes available with 40 km/h 24.9 mph TLS with front brakes standard with 50 km/h 31 mph |

| Front axle differential lock | 1300 Series MFWD: Limited slip TLS: Limited slip TLS with front brakes: Full-locking electrohydraulic (actuated at same time as rear diff lock) |

| Load rating | |

Tires | |

| Rear | RCI Group 48/49 |

| Wheel tread range | |

| Turning radius with brakes | 600/70R30 group 43 tires at 188.2-cm (74.1-in.) spacing, TLS: 6.7 m 22 ft 620/75R30 group 44 tires at 208.3-cm (82-in.) spacing, TLS: 8.7 m 28.5 ft |

| Turning radius without brakes | |

| Central Tire Inflation System (CTIS) | |

| Front | |

Tracks | |

| Tread spacing | |

| Drive type | |

| Track width | |

| Mid-rollers | |

Steering | |

| Type | Standard: Hydraulic power-steering with electric pump back-up Optional: ActiveCommand Steering 2 (ACS2) w/ electronic back-up pump |

Brakes | |

| Primary brake (foot brake) | |

| Secondary brake | |

| Park lock | |

| MFWD braking | |

| Front axle brakes | |

| Auxiliary brakes | |

| Hydraulic trailer brakes | |

| Pneumatic trailer brakes | |

Electrical system | |

| Alternator size | Standard: 210 amp Optional: 250 amp |

| Battery options | 12 V |

| Working lights | Standard: 18 halogen Available: 18 LED or 22 LED |

| Type of bulb in headlight (Halogen, Zenon, LED) | Standard: 65-W halogen Available: LED |

| Type of bulb in beacon (Halogen, Zenon, LED) | |

| dB(A) rating for backup alarm | |

| Total cold cranking amps | With two 925 CCA group 31 batteries: 1850 CCA |

Operator station | |

| Rollover protective structure, OOS | |

| Seat | Degree of seat swivel, left hand Optional: 25 degree Degree of seat swivel, right hand 40 degree Standard: air suspension Optional: ActiveSeat™ II |

| Cab suspension | Optional |

| Instructional seat | Standard |

| Display | Standard: 4600 Generation 4 CommandCenter™: 25.4 cm 10 in. |

| Radio | Standard: AM/FM stereo with weatherband, remote controls, auxiliary input jack, four speakers and external antenna |

| Inner cab volume | 3.24 m3 114 cu ft |

| dB(A) rating | |

| Cab glass area | 6.56 m2 70.61 sq ft |

| Safety glass rating | |

| Front visibility | |

Dimensions | |

| Wheelbase | 2,925 mm 115.2 in. |

| Overall width | |

| Overall length | 5,540 mm 218 in. |

| Overall height | |

| Drawbar clearance | Group 48 rear tires: 415 mm 16.3 in. Group 49 rear tires: 461 mm 18.1 in. |

| Front axle center | |

| Approximate shipping weight, Open;Cab | |

Weight | |

| Base machine weight | e23, TLS, 18.4R46: 10,000 kg 22,000 lb |

| Maximum ballast level | SAE PTO hp: 61.2 kg 135 lb |

| Maximum permissible weight | |

Capacities | |

| Crankcase oil volume | 23 L 6.1 U.S. gal. |

| Fuel tank | e23™: 463 L 122 U.S. gal. IVT: 513 L 135 U.S. gal. |

| Diesel exhaust fluid (DEF) tank | 26.2 L 6.9 U.S. gal. |

| Cooling system | 44.5 L 11.8 U.S. gal. |

| Transmission-hydraulic system | 160 L 42.3 U.S. gal. |

Serviceability | |

| Interval for engine oil change | 500 hours |

| Interval for hydraulic/transmission oil change | 1,500 hours |

| Interval for engine coolant change | 6,000 hours |

Loaders | |

| Loader | 700M |

| Lift capacity at full height | 2417 kg 5304 lb |

| Maximum lift height | 4741 mm 186 in. |

| Leveling type | |

Precision AG | |

| Guidance | Integrated AutoTrac™ |

| Telematic | JDLink™ |

| Remote diagnostics | ServiceADVISOR™ Remote: available with JDLink hardware and activations Remote Display Access: available with JDLink hardware and activations |

Miscellaneous | |

| AutoTrac ready | |

| ISOBUS ready | |

| CommandCenter video inputs | |

| Immobilizer | |

| Side slope rating | |

| Uphill/downhill slope rating | |

| Country of manufacture | USA |

Additional information | |

| Date collected | 10-Jul-2020 |