N530C

Central Commodity System (CCS™)

- Quick Change Blade enhancement of the ProSeries™ Opener reduces change time by up to 45%1

- Electric drive with Section Control

- Wide variety of working widths and row spacings

- Premium Lighting and easier access to meters

- Quick Change Blade enhancement of the ProSeries™ Opener reduces change time by up to 45%1

- Electric drive with Section Control

- Wide variety of working widths and row spacings

- Premium Lighting and easier access to meters

- Quick Change Blade enhancement of the ProSeries™ Opener reduces change time by up to 45%1

- Electric drive with Section Control

- Wide variety of working widths and row spacings

- Premium Lighting and easier access to meters

- Quick Change Blade enhancement of the ProSeries™ Opener reduces change time by up to 45%1

- Electric drive with Section Control

- Wide variety of working widths and row spacings

- Premium Lighting and easier access to meters

Features

John Deere has the seeding solutions that go above expectations with a complete line of everything needed in small grains. Offering a variety of openers for your chosen practice in a variety of configurations and sizes. All with integrated technology throughout the seeding train allows for effortless setup and seamless documentation.

Total seeding solution

Total seeding solution

Setting up a John Deere seeding train is quick and easy with the plug and play technology. All data and technology operate through the Gen 4 display and ultimately up to John Deere Operation Center™ that can be viewed from anywhere at any time. Not only does the complete John Deere seeding solution all operate through one display but it eliminates the difficulty and time-consuming tasks of setting up extra displays and harnesses.

John Deere tractor paired with John Deere tool and cart

John Deere tractor paired with John Deere tool and cart

With a complete John Deere seeding solution, there are multiple different onboard and offboard technologies shown below that improve the overall seeding production step. Many of these technologies are exclusive to John Deere. Each of these technologies bring different customer value that overall lead to the ultimate John Deere seeding solution!

On the go, quick adjust downforce with TruSet™ from the cab

- Adjust downforce pressure to improve uniform emergence

- Set presets to quickly adjust from field to field

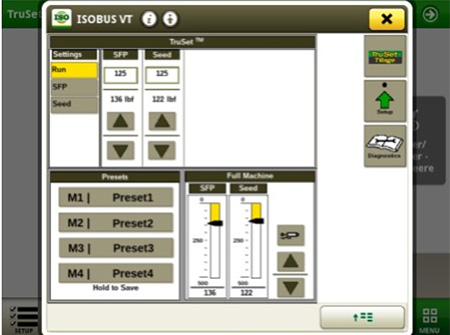

TruSet downforce display

TruSet downforce display

Monitor blockage row by row from the cab with RelativeFlow™

- Seed with confidence while monitoring each row

- Detect blockage early and know exactly where it is

RelativeFlow blockage sensors

RelativeFlow blockage sensors

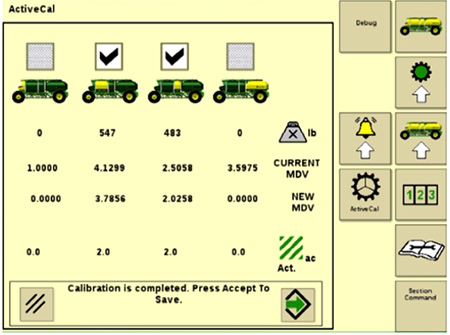

ActiveCal™ display

- Calibrate the meters from the cab utilizing the tank scales

- Improved confidence the correct seeding rates are being met

ActiveCal display

ActiveCal display

SectionCommand™ controls seed and fertilizer output

- Controls seed and fertilizer output by closing and opening gates on the meters

- Minimize skips and overlaps leading to reduced inputs

Example of seeded field with SectionCommand

Example of seeded field with SectionCommand

AutoTrac™ Implement Guidance and AutoTrac Turn Automation

- Make every operator an experienced operator

- Precisely placed implements for more accurate seeding, less operator fatigue, and more productivity

- Hands-free turns within field headlands (with AutoTrac Turn Automation enabled)

AutoTrac Turn Automation display

AutoTrac Turn Automation display

John Deere Operation Center™

- Setup and manage your farm operations: equipment, team, fields, and crop inputs

- Plan work in advance to increase job quality and efficiency with Work Planner

- Map based prescriptions can be used with variable rates

- Analyze this season’s results to improve next season’s crops

John Deere Operation Center web and mobile

John Deere Operation Center web and mobile

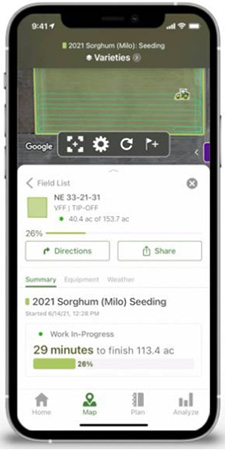

Operation Center Mobile

- View your data on the go; remotely monitor job quality, productivity, machine performance, and quickly make informed decisions

- Manage and monitor from anywhere at any time with near real-time field and machine updates

Operation Center Mobile

Operation Center Mobile

Connected Support

- Expert Alerts proactively notifies your dealer of any issues

- Remote display access allows for easy on the go support

Connected Support

Connected Support

For more information regarding Large Tractors and Precision Ag, view the following landing pages

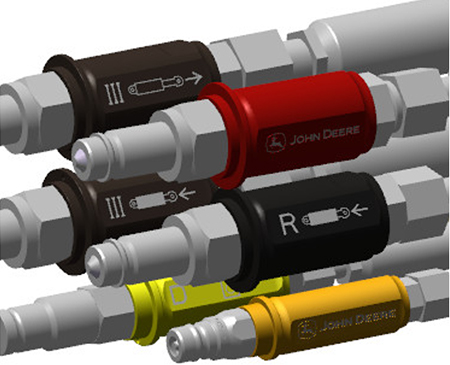

John Deere color-coded hydraulic hose handles

John Deere color-coded hydraulic hose handles

Hydraulic connections on rear of 9R Tractor

Hydraulic connections on rear of 9R Tractor

These color-coded aluminum hydraulic hose handles make connecting hydraulic hoses from the air seeder to the correct function on the tractor easier than before. The anti-slip diamond shaped design makes it easy to grip the hose and connect or disconnect from the back of the tractor. Each color is laser engraved with the John Deere logo and extend/retract icons to ensure proper matching to the proper function.

- Easily identify function of each hose

- Consistently match hose handles colors to rear couplers on tractor

- Easy to grip for connecting or disconnecting

Code |

Description |

Compatible Tools |

Base |

Color-coded hydraulic hose handles |

N500s, N500Fs, N500Cs |

The tank on the N500C has been moved up and back to allow for better access to the meters. The blower fan has been relocated to the front of the tank to allow non-obstructed access to all four meters.

Rear of N500C machine

Rear of N500C machine

Relocated blower fan

Relocated blower fan

Easy meter access

Easy meter access

The updated tank design is also larger. The 9.15-m (30-ft) to 11-m (36-ft) models offer a 3523.9 -L (100-bu) tank. The 12.2-m (40-ft) and 12.8-m (42-ft) models offer a 4228.7-L (120-bu) tank.

3523.9-L (100-bu) tank

3523.9-L (100-bu) tank

Tank cleanout has also been improved. Producers can place a seed box or conveyer under the tanks to empty out excess seed. The tank has been designed so there is minimal seed left in the tank after it has been emptied.

Cleanout with a seed box

Cleanout with a seed box

Cleanout with seed tender

Cleanout with seed tender

Calibrating the meters has also been improved thanks to electric drive metering. The N500C is calibrated stationary similar to larger air carts. Catch bags are placed under each meter, and the meters turn a pre-determined amount of revolutions. Catch bags are weighted and entered into the Equipment Mobile app or on the Gen 4 display in order to generate a meter displacement value (MDV).

Calibrating the meters

Calibrating the meters

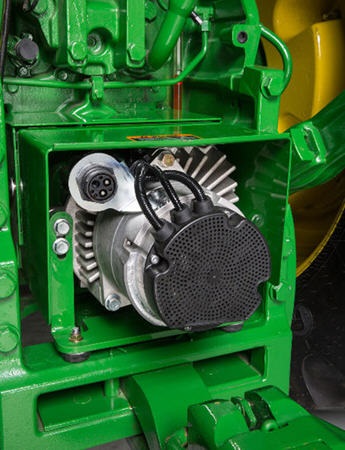

For the first time, meter sections are controlled with electric motors. Each meter section has its own electric drive motor. This eliminates the need for a variable-rate drive hydraulic motor or a ground drive wheel. This also enables the SectionCommand system and variable/prescription seeding.

Electric drive motor on meter

Electric drive motor on meter

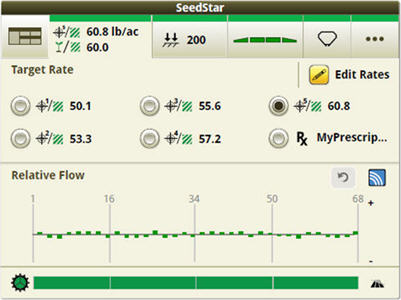

SeedStar run page showing four sections and prescription (Rx) seeding

SeedStar run page showing four sections and prescription (Rx) seeding

Prescription/variable-rate seeding allows growers to apply the right amount of seed depending on predetermined management zones. Four-section SectionCommand has shown a potential seed savings of 4 to 6 percent depending on field size and shape.

Power generation

The electric motors can be powered by a DC/DC converter, a power take-off (PTO) power generation unit, or an onboard hydraulic power generator. Growers can choose either of these options based on their needs. In most cases, the DC/DC convertor will be the best option. It utilizes power coming from the tractor though the ISOBUS nine-pin connector and converts it to 56 V; this results in fewer moving parts and decreases the opportunity for downtime to occur. The onboard hydraulic system utilizes power beyond, whereas the PTO system frees up hydraulic capacity on the tractor as the PTO powers the generator.

DC/DC power generation

DC/DC power generation

PTO power generation

PTO power generation

Onboard hydraulic power generation

Onboard hydraulic power generation

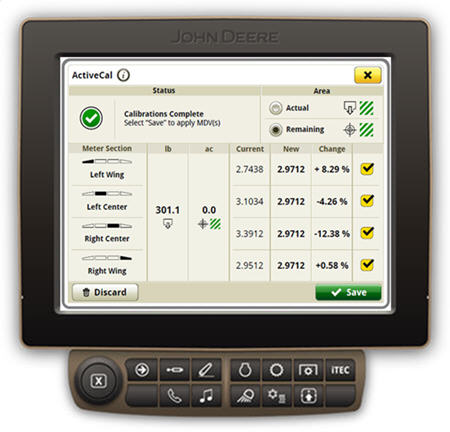

ActiveCal initiated on C-Series Air Carts

ActiveCal initiated on C-Series Air Carts

ActiveCal initiated on an N500C

ActiveCal initiated on an N500C

The more frequently you calibrate your seeding equipment, the more accurate it will be. With ActiveCal, available only from John Deere on the N500C and C-Series Air Carts, you can do all the calibration from your cab to minimize variation in product metering. It takes only minutes, so there’s no need for back-and-forth trips to the cart. ActiveCal is designed to recalibrate itself throughout your work day to give you confidence in changing product weight and weather conditions.

A number of variables, including product weight and changing climate conditions throughout the day, will have an effect on any volumetric metering system; with the John Deere ActiveCal system, calibration can be done from the cab of the tractor, while seeding, to minimize the variation in product metering.

The process to calibrate the implement starts with the Gen 4 4600 CommandCenter™ Display in the work setup page, where the operator defines product types, rates and selects meter rollers. Based on information entered into the work setup page, a preconfigured meter displacement value (MDV) will populate per meter. An initial manual calibration will give the most accurate MDV to start with. However, the preconfigured MDV will be a good starting point for growers who do not wish to manually calibrate.

The operator engages ActiveCal while stationary by selecting the button on the screen and then begins seeding. When enough product has been metered out, typically after about 3.2 to 4.9 ha (8 to 12 acres), the Gen 4 CommandCenter will prompt the operator to stop when convenient to do so. At that time, the data points are calculated and a new MDV with percent difference is displayed on screen. The operator can accept or reject the new MDV. If accepted, the system automatically calibrates to the new MDV. If rejected, the system continues at the previously calibrated numbers.

Tank scales provide tank weights to ActiveCal system

Tank scales provide tank weights to ActiveCal system

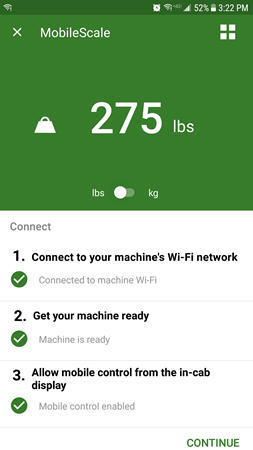

Equipment Mobile app home screen

Equipment Mobile app home screen

Tank scale weights and meter calibrations can be completed from an Android™ or iOS® mobile device anywhere around the machine.

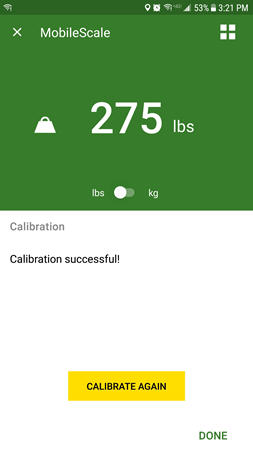

Calibrating tank scales

Calibrating tank scales

Calibration complete

Calibration complete

Tank scale weights can be viewed anywhere within 15.2 m (50 ft). The Equipment Mobile app can also be used to calibrate the tank scales as needed.

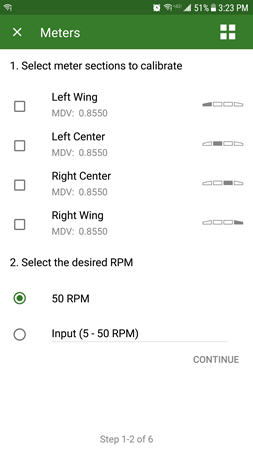

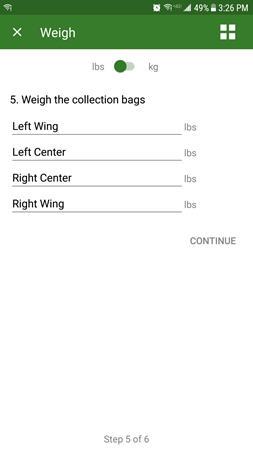

Initial meter calibration

Select meters to calibrate

Select meters to calibrate

Select the meters that toned to be calibrated. Calibrations are recommended every morning or when crops/seed sizes are changed.

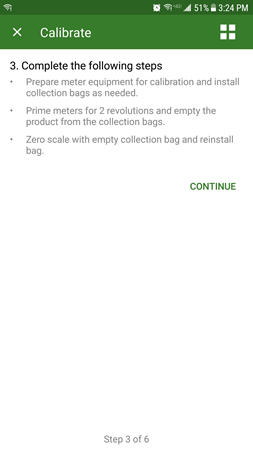

Steps to complete calibration

Steps to complete calibration

Follow the on-screen prompts to complete the calibration.

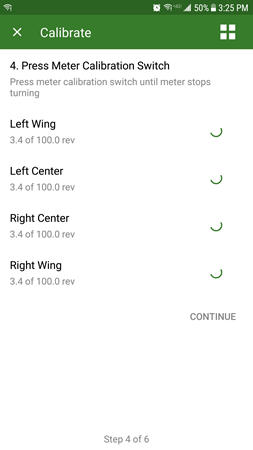

Press meter calibration switch

Press meter calibration switch

Once the catch bags are in place, hold down the meter calibration switch until the number of revolutions is complete.

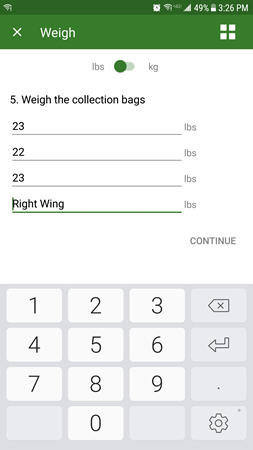

Weights of bag for each meter

Weights of bag for each meter

Entering the weight of the bags

Entering the weight of the bags

Enter the weights of the bags into the app.

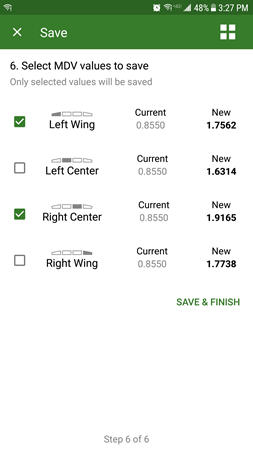

Save meter displacement values (MDV)

Save meter displacement values (MDV)

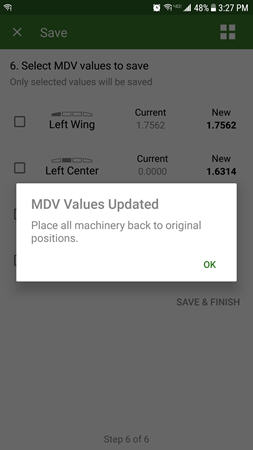

MDV values are updated

MDV values are updated

The Equipment Mobile app will calculate MDV based on the number of revolutions and the product weights. Operators can choose to accept the proposed MDV values or not.

Android is a trademark of Google LLC. iOS is a trademark of Cisco Technology, Inc. used under license by Apple Inc.

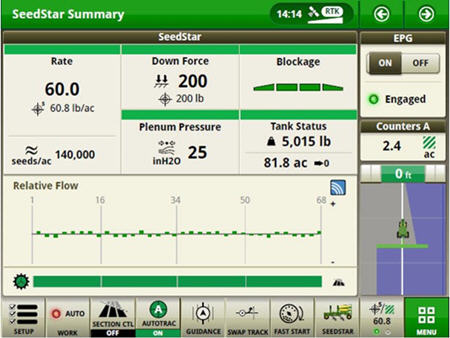

With RelativeFlow Blockage sensing, operators can see the flow of both seed and fertilizer from inside the tractor cab. Sensors on all secondary hoses monitor the relative product flow row to row, giving you a better view of the flow rate of both seed and fertilizer from the cart to the opener from inside your tractor cab. This technology can help you identify any problems before a potential blockage occurs.

RelativeFlow Blockage is available in all run configurations on the following models (all widths):

- H500

- H500F

- P500

- P600

- N500

- N500F

- N500C

- 730LL

RelativeFlow Blockage is compatible with hydraulic drive carts: model year 2014 and newer 1910, all 19,381.5-L (550-bu) 1910 Carts, and C650 and C850 Air Carts.

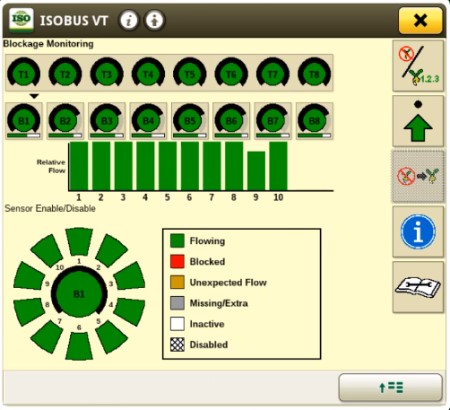

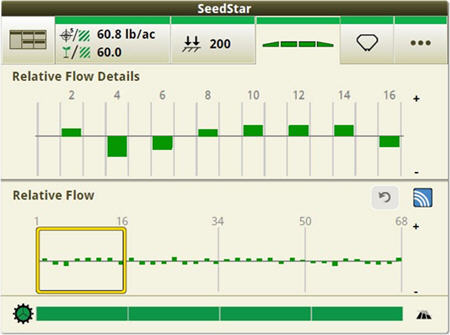

Below are the Gen 4 display screens for the blockage monitoring system. For complete details and information, see the owner’s manual.

Blockage monitoring screen on Gen 4 display

Blockage monitoring screen on Gen 4 display

The RelativeFlow Blockage sensing chart shows the amount of flow through each sensor on the selected tower. Sensitivity for the blockage system can be adjusted if desired, as shown below.

Blockage Setup screen on Gen 4 display

Blockage Setup screen on Gen 4 display

Blockage warning sensitivity allows the producer to set and change the sensitivity of the sensors to meet their preferences and varying crop/fertilizer types. Increasing the sensitivity means the system is more likely to show a false blockage, while less sensitivity means the system is more likely to miss a blockage.

Multiple run-page alarm behavior options are available for selection.

Blockage monitoring screen on Gen 4 display

Blockage monitoring screen on Gen 4 display

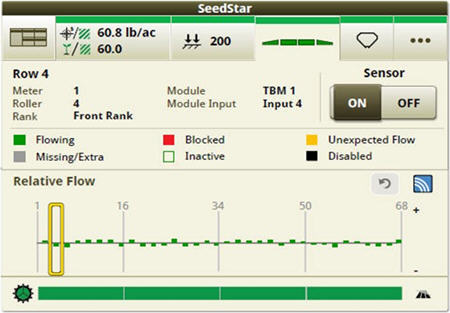

Below are the Gen 4 display screens for the blockage monitoring system on the N500C.

For complete details and information reference, the owner’s manual.

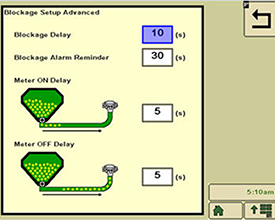

RelativeFlow Blockage configured run page

RelativeFlow Blockage configured run page

The SeedStar™ system run page displays the five major run settings. Clicking on any of the tiles will take an operator to that specific page (shown below).

Operators can zoom into flow details by meter section when selecting blockage tiles

Operators can zoom into flow details by meter section when selecting blockage tiles

Operators can zoom into the row level to access row/sensor information and turn a sensor on/off independently

Operators can zoom into the row level to access row/sensor information and turn a sensor on/off independently

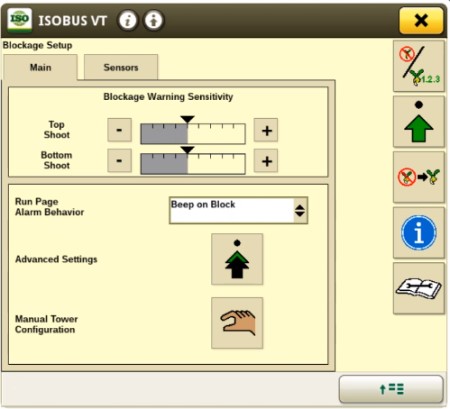

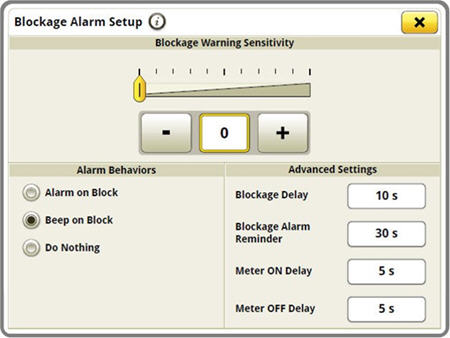

Blockage sensitivities and alarm delays are all set up on one easy-to-navigate screen

Blockage sensitivities and alarm delays are all set up on one easy-to-navigate screen

Blockage alarm delays can be set up by clicking on the advanced settings button from the blockage set-up screen.

- A blockage delay is how long a blockage should occur before an alarm is sounded.

- The blockage alarm reminder is how often the alarm should sound when a blockage occurs.

- The meter on delay is the time from when the meter is turned on until the blockage sensor should start monitoring for blockage.

- The meter off delay is the time from when the meter is turned off until the blockage sensor should start monitoring to verify no flow.

For more detailed information, see the owner’s manual.

Air tools with RelativeFlow Blockage are not compatible with 1910 air carts with ground drive.

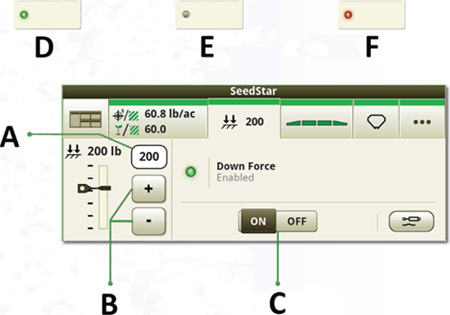

Downforce control from the Gen 4 display

Downforce control from the Gen 4 display

TruSet downforce allows operators to set downforce pressures from inside the cab. Downforce can easily be changed by the push of a button as soil conditions very. Proper downforce is directly related to a consistent seeding depth, which leads to improved even emergence, plant density, and maturity.

TruSet system quick-reference guide

TruSet downforce settings:

A. Select to manually input a value

B. Select to increase or decrease the target force of the openers

C. Downforce toggle button: select to enable or disable the downforce

D. Indicates that the downforce is enabled

E. Indicates that the downforce is disabled

F. Indicates that the downforce is enabled but not applying

The N500C offers 33x15.5R16.5 tires standard on all machines, resulting in better floatation and less compaction and allowing operators to get into the field sooner and stay in the field longer. The mainframe is also equipped with walking beams to allow for better ground following.

500/40R16.5 tires with walking beam

500/40R16.5 tires with walking beam

33x15.5R16.5 tires with walking beam

33x15.5R16.5 tires with walking beam

31x13.5R15 tires on wing frame

31x13.5R15 tires on wing frame

| Option code | Width | Mainframe front tire size | Number of tires | Mainframe rear tire size | Number of tires | Wing frame tire size | Number of tires |

| 3610 | All | 33x15.5R16.5 | 4 | 33x15.5R16.5 | 4 | 31x13.5R15 | 4 |

| 3611 | All | 33x15.5R16.5 | 4 | 33x15.5R16.5 | 4 | 31x13.5R15 | 8 |

| 3612 | 9.5/11-m (30/36-ft) |

33x15.5R16.5 | 4 | 500/40R16.5 | 4 | 33x15.5R16.5 | 8 |

| 3613 | 12.2/12.8-m (40/42-ft) |

500/40R16.5 | 4 | 500/40R16.5 | 4 | 33x15.5R16.5 | 8 |

Tire area comparison

Tire area comparison

N500C with SeedMetering2

N500C with SeedMetering2

N500C in the field

N500C in the field

The N500C is designed for no-till seeding. The N500C with SeedMetering2 offers accurate volumetric metering in a compact tank-mounted-on-frame design, with the convenience of the Central Commodity System (CCS™) bulk-fill capabilities.

The N500C is available in single- or dual-rank designs, with 9.15-m, 11-m, 12.2-m, and 12.8-m (30-ft, 36-ft, 40-ft, and 42-ft) working widths. The single-rank N500C is available in 38.1-cm (15-in.) row spacing, making for a highly productive soybean seeding machine, while the dual-rank models are available in 19-cm or 25.4-cm (7.5-in. or 10-in.) row spacings. The dual-rank models also feature an optional dual row spacing package, which allows them to seed in their standard spacing or lock-up one rank and seed in 38.1-cm or 50.8-cm (15-in. or 20-in.) row spacings.

The productivity of the CCS comes standard with the N500C. The CCS bulk-fill tanks feature 3523.9-L (100-bu) capacity on the 9.15-m (30-ft) to 11-m (36-ft) models. The 12.2-m (40-ft) and 12.8-m (42-ft) models offer 4228.7 L (120 bu) of capacity to allow operators to seed more acres before stopping to refill.

The N500C features the Pro-Series™ No-Till Openers. With well over one million no-till openers in the field today, this proven opener offers accurate seed placement with the exclusive active hydraulic downforce ground-following system while minimizing moisture loss with its low-disturbance opener design.

ProSeries Openers

ProSeries Openers

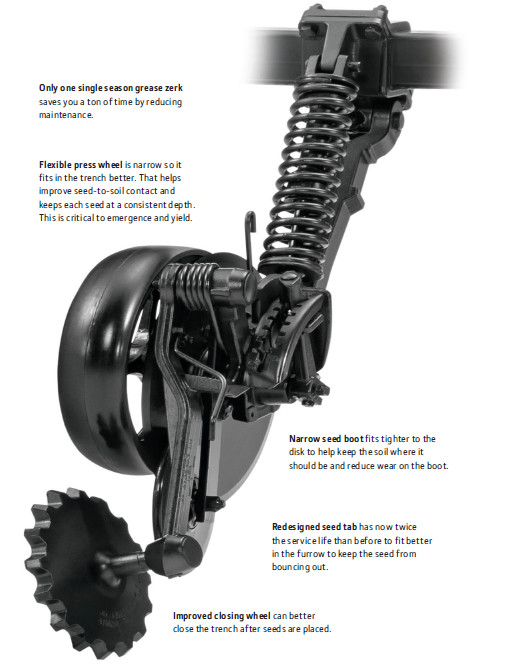

The ProSeries Opener is John Deere’s most advanced opener for your seed and separate fertilizer placement. When it comes to seeding precision, consistent seed depth, and uniform emergence in virtually all field conditions, you can superSEED your expectations with ProSeries.

Two of the three daily grease points were removed. The only remaining grease point is a yearly interval. The narrow seed boot travels behind the shadow of the blade, causing less soil disturbance. When attaching the boot to the shank, the bolt has been replaced with a flag pin. Now the flag pin is the wear point, not the casting, reducing overall maintenance. The seed press wheel is also redesigned; it has a narrow profile, a double-wall bearing, and is made of a flexible material. The quick-change blade feature reduces the time it takes to change each blade, saving time and money. Lastly, the seed tab is UV resistant and profiled similar to the trench. There is also the added option of the serrated closing wheel.

ProSeries Openers are in base equipment on all N500 and N500F Separate Fertilizer Placement (SFP), N500C, 1990 Central Commodity System (CCS™), and 1590 Air Drills.

The ProSeries Openers:

- Work not only in no-till conditions, but also in minimum or reduced-till conditions

- Provide 51 mm (2 in.) of free travel in the opener before spring down pressure takes over

- Benefit: allows the opener to move over uneven ground conditions and minimize the chance of the gauge wheels bulldozing soil in soft or mellow conditions

- The opener spring travels a maximum of 203-mm (8-in.) up or 150-mm (6-in.) down before the hydraulics react to uneven seedbeds

Specs & Compare

Key Specs | N530C Current Model |

| Working widths | 9.15 m 30 ft |

| Spacing | Dual rank: 7.5-in. (19.1 cm) spacing; 10-in. (25.4 cm) spacing Single rank: 15-in. (38.1 cm) spacing |

| Number of ranks | Single; Dual |

| Openers | Style No-till Rank lock-up Individual Diameter 45.7 cm 18 in. Down pressure 74.8-181.4 kg/opener (165-400 lb) Dual rank - 7.5-in. (19.1 cm) spacing: 48 Dual rank - 10-in. (25.4 cm) spacing: 36 Single rank - 15-in. (38.1 cm) spacing: 24 |

Sizes | |

| Working widths | 9.15 m 30 ft |

| Spacing | Dual rank: 7.5-in. (19.1 cm) spacing; 10-in. (25.4 cm) spacing Single rank: 15-in. (38.1 cm) spacing |

| Number of ranks | Single; Dual |

| Number of sections | |

Dimensions | |

| Transport height | < 3.68 m < 12.08 ft |

| Transport width | < 4.42 m < 14.5 ft |

| Road clearance | > 17.8 cm > 7.0 in. |

| Overall length | ≤ 9.1 m ≤ 29.9 ft |

| Centerframe width | 3.5 m 11.4 ft |

| Centerline of mainframe wheel support tube to centerline of wing wheel support tubes | 2.4 m 7.85 ft |

| Weight before ballast | Dual rank - 7.5-in. (19.1 cm) spacing: ≤ 23,000 lb. (10,400 kg) Dual rank - 10-in. (25.4 cm) spacing: ≤ 20,400 lb. (9300 kg) Single rank - 15-in. (38.1 cm) spacing: ≤ 14,700 lb. (6700 kg) |

| Available ballast | 800 lb |

| Frame | Cross members 102x152 mm 4x6 in. End tubes 51x152 mm 2x6 in. Hitch 254x152 mm 10x6 in. |

| Lateral frame clearance, opener to opener | 15 in. (38.1 mm) for 7.5-in (19.1 cm) models |

| Clearance from rank to rank | 134 cm 52.8 in. |

| From ground to top of lid | ≤ 320 cm (126 in.) |

| From ground to platform | ≤ 220 cm 85 in. |

| From ground to top of safety rail | ≤ 322.6 cm 127 in. |

| From ground to top of lights | ≤ 320 cm (126 in.) |

Tires | |

| Mainframe standard | (4) 33x15.5-16 on front, (4) 33x15.5-16 on rear |

| Mainframe bolt pattern | |

| Wings standard | (4) 31x13.5-15 NHS |

| Wings bolt pattern | |

| Centerframe tires and wheels | (4) 33x15.5-16 on front, (4) 500/40R16 on rear |

| Wing tires and wheels | (8) 33x15.5-16 |

| Wheel spacing, center frame | Width of duals, center to center 258.1 cm (101.6 in.) Width outside to outside of dual pair, front - largest tire option 130.8 cm 51.5 in. Width outside to outside of dual pair, rear 130.8 cm 51.5 in. Tire width, front - largest tire option 40.6 cm (16 in.) Tire width, rear - largest tire option 50.8 cm 20 in. |

Openers | |

| Style | No-till |

| Rank lock-up | Individual |

| Disk | Diameter 45.7 cm 18 in. Angle 7-degree angle 45.7 cm (18-in.) disk blade at 7-degree angle |

| Down pressure | Style Hydraulic rank 74.8-181.4 kg/opener (165-400 lb) |

| Depth control | Description Gauge wheel (smooth sided or spoked) Gauge wheel size 4.5x16 in. 11.4x40.6 cm Range 0.5-3.5 in. (1.3-8.9 cm) Increments 0.25 in. (0.64 cm) |

| In-Furrow press wheel | Material Rubber Packing force Adjustable down-pressure from 2.3 to 20.4 kg 5 to 45 lb 2.54x25.4 cm 1x10 in. |

| Furrow closing | Description Cast wheel at 15-degree vertical angle Serrated closing wheel at 15-degree vertical angle Size Cast wheel: 2.54x30.5 cm 1x12 in. Material Cast Down force Down-pressure from 11.8-19.5 kg 26-43 lb Serrated or smooth cast closing wheel |

| Double-Shoot capable | |

Seed Metering | |

| Description | Central volumetric metering |

| Crops | Barley, oats, rice, sorghum, soybean, wheat |

| Max Volumetric Seeding Rates - Barley | ≤ 1,000,000 seeds per acre (2,470,000 seeds per hectare) |

| Max Volumetric Seeding Rates - Oats | ≤ 2,500,000 seeds per acre (6,180,000 seeds per hectare) |

| Max Volumetric Seeding Rates - Rice | ≤ 1,700,000 seeds per acre (4,200,000 seeds per hectare) |

| Max Volumetric Seeding Rates - Milo/Sorghum | ≤ 100,000 seeds per acre (247,000 seeds per hectare) |

| Max Volumetric Seeding Rates - Soybean | ≤ 250,000 seeds per acre (618,000 seeds per hectare) |

| Max Volumetric Seeding Rates - Wheat | ≤ 2,970,000 seeds per acre (7,300,000 seeds per hectare) |

| Metering Drive Type | Electric |

Seed Storage | |

| Tank Description | Central, non-pressurized polyethylene tank |

| Total Tank Capacity | 3500 L (100 bu) |

| Tank Fill Screen | Optional; one per tank opening |

| Tank Scales | Optional; provides summed commodity weight |

| Seed Distribution | |

| Type | Pneumatic |

| Blower | 45 cm (17.7 in.) diameter impeller |

| Blower drive type | Hydraulic |

| Distribution hose size | 1 in. (2.54 cm) ID for 38.1 cm (15 in.) row spacing 1.13 in. (3.13 cm) ID primaries with 1 in. (2.54 cm) ID secondaries for 19.1 and 25.4 cm (7.5 and 10 in.) row spacings |

Equipment compatibility (at 1.5 in. seeding depth and 8 mph) | |

| Tractor drawbar power required, 7.5-in (19.1 cm) models | ≥ 219 kW (293 hp) |

| Tractor drawbar power required, 10-in (25.4 cm) models | ≥ 179 kW (240 hp) |

| Tractor drawbar power required, 15-in (38.1 cm) models | ≥ 137 kW (183 hp) |

Tractor requirements | |

| Minimum number of SCV's | Three - one fold, one opener raise/lower, one seed distribution blower |

| Hydraulic Power Beyond | Required for in-cab opener downforce and electric power generation |

| Minimum hydraulic capacity | 21.4 gpm (81 L/min) at 2900 psi (200 bar) |

| Minimum electrical capacity | 48 A at 12 VDC |

Additional information | |

| Tool-mounted alternator | 56 VDC Optional: 56 VDC |

| Implement harness connection, 56 VDC | Power take-off (PTO) power gen |

| Implement harness connection, 12 VDC | 7-pin SAE, 9-pin ISO |

| Operator interface | Description: QT / Gen 4 Language: English, Spanish, English/Spanish, English/French |

| Four-section seed on/off | Standard |

| Fast start/Quick start | Standard |

| Seed blockage sensor per row | Standard |

| Date collected | 1 March 2019 |