1590

No-Till Drill

- Productive Seedbox capacities

- Easy-to-read seed level indicator

- Accurate fertilizer metering

- Box drill acremeter

- Productive Seedbox capacities

- Easy-to-read seed level indicator

- Accurate fertilizer metering

- Box drill acremeter

- Productive Seedbox capacities

- Easy-to-read seed level indicator

- Accurate fertilizer metering

- Box drill acremeter

- Productive Seedbox capacities

- Easy-to-read seed level indicator

- Accurate fertilizer metering

- Box drill acremeter

Features

Electronic population rate control

Electronic population rate control

With seed prices on the rise, producers want the ability to monitor and control seed populations on the go.

Electronic population rate control (EPRC), in base equipment on the 1590 Drill, allows producers to adjust the population rate right from the convenience of their tractor cab.

The system:

- Features an in-cab rocker switch to adjust the electric motor that controls the population rate

- Is manually adjusted – the operator must hold down the adjustment switch until the desired rate is met

- Can be overridden by pushing back on the motor to allow the producer to make a manual adjustment to the rate if needed

NOTE: To give producers the ability to monitor the population rate on the go, it is highly recommended they equip the unit with a ComputerTrak™ monitor or SeedStar™ population monitoring.

NOTE: One system is used with 3.05-m (10-ft) and 4.6-m (15-ft) drills. The 6.1-m (20-ft) models require two systems.

Seedbox

Seedbox

Seedboxes have large capacity for longer intervals between stops for refilling.

Plain grain or combination grain/fertilizer seedboxes are available to match the producer's needs and crops.

The versatile grain/fertilizer box with 19-mm (7.5-in.) row spacing can be set for 100 percent grain or 60 percent grain/40 percent fertilizer.

The bulkheads in the seedbox reduce material shifting in the box for increased seeding efficiency.

The sight glass located near the end of the box on combination grain fertilizer drills allows the operator to view seed level at a glance.

Seedbox capacities |

|||

| Plain grain | Combination grain/fertilizer |

||

100 percent grain |

60 percent grain/40 percent fertilizer |

||

| Grain, bu/ft (L/m) | 3.5 (405) |

3.5 (405) |

2.1 (243) |

| Fertilizer, bu/ft (L/m) | --- |

--- |

1.4 (162) |

| Total, bu/ft (L/m) | 3.5 (405) |

3.5 (405) |

3.5 (405) |

| Plain grain box | Combination box | |

| Total box - 3.05 m (10 ft) | 1233.4 L (35 bu) | 1317.9 L (37.4 bu) |

| Total box - 4.6 m (15 ft) | 1850.1 L (52.5 bu) | 2026.2 L (57.5 bu) |

| Total box - 6.1 m (20 ft) | 2466.7 L (70 bu) | 2635.9 L (74.8 bu) |

Capacities with grass seed attachment

| 3.05 m (10 ft) | 4.6 m (15 ft) | 6.1 m (20 ft) | |

| Grass seed box with plain grain box | 105.7 L (3 bu) | 169.1 L (4.8) | 211.4 L (6 bu) |

| Grass seed box with combination box | 52.9 L (1.5 bu) | 84.6 L (2.4 bu) | 105.7 L (3 bu) |

Seed tube

Seed tube

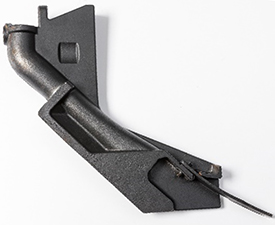

A long, internally smooth seed tube with a molded elbow is supported at the seed tube support. From there, it is connected to a short convoluted seed tube, allowing product to flow smoothly to the openers and still flex.

The tube flexes to avoid crimping for consistent seed flow. It is made of non-corrosive nylon material for long life. Long tubes are 55.4 cm (21.8 in.) and short tubes are 10.8 cm (4.25 in.).

Elbow at meters to angle the seed tube directly to the openers.

The smooth inside diameter provides smooth seed flow from the meters to the furrow openers.

Seed tube with Y-adapter

Seed tube with Y-adapter

The combination grain/fertilizer drill with 19-cm (7.5-in.) row spacing features a convoluted tube directing fertilizer from the discharge hole to the top of the steel seed tube at the seed boot. From there, a special Y-adapter lets seed and fertilizer mix before going into the furrow.

Seed placement with ProSeries™ Opener

Seed placement with ProSeries™ Opener

1590 Series down pressure

1590 Series down pressure

ProSeries single-disk no-till openers are included in base equipment. The single-disk openers are mounted on one rank on the 38.1-cm (15-in.) row spacing single rank units and on two ranks on the 19-cm (7.5-in.) and 25.4-cm (10-in.) row-spacing units. The single-disk openers provide consistent and accurate seed placement.

The single-disk openers are gang mounted and are hydraulically raised and lowered. The hydraulics also work to provide a wide range of downforce settings for the openers.

The active hydraulics work in conjunction with the opener spring to provide an adjustable range of 74.8 kg to 181.4 kg (165 lb to 400 lb) of down pressure per opener to penetrate hard soils and heavy residue.

The down pressure is easily adjusted with the pressure valve located on the front of the mainframe, giving the operator the ability to quickly adjust, or dial in, the down pressure as operating conditions change.

For additional ballast in hard-to-penetrate conditions, tractor suitcase weights may also be added to obtain maximum down pressure per opener. On the 3.05-m (10-ft) and 4.6-m (15-ft) machines, up to 10 weights can be added. On 6.1-m (20-ft) machines, up to 20 weights can be added (10 per side).

The no-till openers work not only in no-till conditions, but also in clean-till conditions. There are 5.1 cm (2 in.) of free travel in the opener before spring down pressure takes over, allowing the opener to move over individual rocks and minimizing the chance of the gauge wheels bulldozing soil in soft or mellow conditions.

Secondly, the opener spring will then travel a maximum of 20.3 cm (8 in.) up or 15.2 cm (6 in.) down before the hydraulics react to uneven seedbeds.

Lastly, the cylinders will allow the openers to travel up or down an additional 40.6 cm (16 in.) with active hydraulic down pressure to follow the ground. The hydraulics will give the openers additional pressure when needed or allow the openers to go into relief if the pressure becomes too high.

Narrow seed boot

Right-side view of seed boot

Right-side view of seed boot

Left-side view of seed boot

Left-side view of seed boot

On the ProSeries Opener, the seed boots are made of the same material as the older high-wear boots previously offered, which is a highly abrasion-resistant white iron. However, this seed boot is narrower, causing less soil throw on neighboring rows. It also sits up tight to the disk blade, resulting in less wear on the boot.

Seed boot

Seed boot

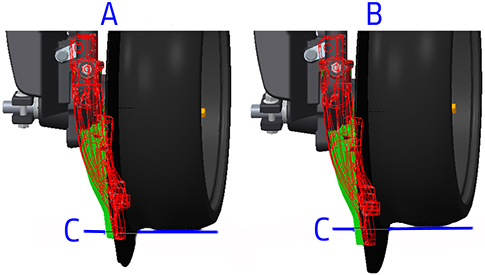

Below are two diagrams showing the seed boot comparison from the 90 Series Opener (highlighted in green) to the ProSeries Opener (highlighted in red). In these diagrams, the ProSeries seed boot is narrower and sits up tighter against the disk blade.

Seed boot comparisons

- ProSeries seed boot highlighted in red

- 90 Series seed boot highlighted in green

- A is the boot comparison at a 44.5-mm (1.75-in.) depth

- B is the boot comparison at a 63.5-mm (2.50-in.) depth

- C is the ground plane

Two inside views of seed boots (90 Series in yellow and ProSeries in green)

Two inside views of seed boots (90 Series in yellow and ProSeries in green)

The inlet/entrance diameter is 33 mm (1.3 in.) on the 90 Series and the ProSeries. The seed tube internal diameter is 27.4 mm (1.08 in.). The cross section is larger than the inlet for the 90 Series and ProSeries.

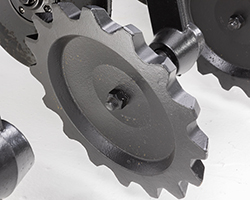

Serrated closing wheel

Serrated closing wheel

Serrated closing wheel

Serrated closing wheel:

- The serrated closing wheel offers an improved closing system when seeding into hard soils or high residue conditions. The notches help break up the top layer of soil covering the seed trench. The notches also reach through residue to seal off the trench better, rather than simply moving residue over the trench. Consistent soil over the seed bed provides optimal germination and emergence. The serrated closing wheel has performed well in all conditions but truly shines in high residue or hard soil conditions.

Smooth closing wheel:

- The smooth closing wheel is still offered for producers who seed into loose soil conditions with little residue. The smooth closing wheel has performed well over the years and has a long-lasting service life, keeping replacement costs down.

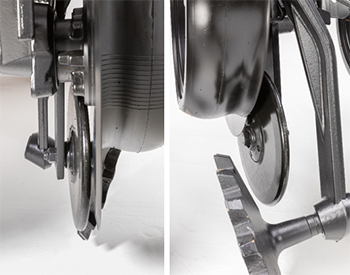

Narrow and flexible press wheel

90 Series press wheel

90 Series press wheel

ProSeries press wheel

ProSeries press wheel

The narrow and flexible press wheel has improved overall seed-to-soil contact. The improvement is in the shape and diameter of the press wheel. The ProSeries Opener press wheel profiles the trench better, partly due to the narrower and more flexible wheel itself, measuring 1.8 cm x 25.4 cm (0.71 in. x 10 in.). The 90 Series press wheel is 1.9 cm x 22.9 cm (0.75 in. x 9 in.).

Front view (left) and side view (right) of press wheel

Front view (left) and side view (right) of press wheel

Growers that have consistent seed depth have a greater opportunity for uniform emergence, uniform tillering, uniform flowering, and uniform maturity. This leads to increased yield potential, easier management of crop, and typically lower harvest loss on canola.

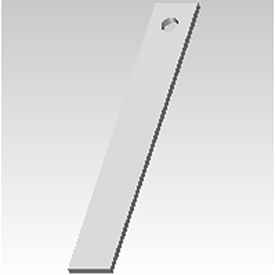

Improved seed tab

ProSeries Opener seed tab

ProSeries Opener seed tab

90 Series Opener seed tab

90 Series Opener seed tab

The ProSeries Opener has an upgraded seed tab that compliments the furrow much better. This seed tab, with an angled edge that profiles the trench better, also allows for consistent seed placement due to the flexible material that was designed to make it less brittle. This also minimizes seed bouncing, which increases overall seeding accuracy.

Spoked gauge wheels

Spoked gauge wheel

Spoked gauge wheel

Spoked gauge wheel

Spoked gauge wheel

Growers have historically had to make some difficult planting and seeding decisions due to weather. Operators have been forced to plant in wet conditions that are far from optimal in order to plant within the optimum planting window. Those operators have experienced poor performance from wet soils working in between the depth gauge wheel and the opener disk and not having a way out. This creates the possibility of the depth gauge wheel or opener disk to seize up and drag through the soil.

The spoked gauge wheel is a solution for operators who plant in these conditions to allow the mud and debris that get caught behind the depth gauge wheel to easily flow through the wheel and continue providing superior depth performance.

The spoked gauge wheel is designed for optimum performance. Its features include serviceable, stamped inner and outer rims. The wheel also has cast spokes and bearing hubs for increased strength. This allows for smaller spokes, creating larger open surface area for mud and debris to flow more easily than competitor’s wheels. Another improvement over the closed gauge wheel is a snap-ring bearing retention. Simply remove the snap ring, replace the bearing, and place the snap ring back.

Narrow gauge wheels leave more stubble standing

Optional 76.2-mm (3-in.) narrow gauge wheels

Optional 76.2-mm (3-in.) narrow gauge wheels

The 76.2-mm x 406.4-mm (3-in. x 16-in.) depth gauging wheel:

- Compatible with all 90 Series and ProSeries Openers

- Provides more clearance between openers for residue flow

- Leaves more stubble standing and disturbs less residue than the 114.3-mm x 406.4-mm (4.5-in. x 16-in.) gauge wheel

Gauge wheel snap ring

Gauge wheel snap ring

Replacing the bearing on the gauge wheel

Replacing the bearing on the gauge wheel

Heavy trash fields from no-till environments have also tested very well with the spoked gauge wheel. Some growers provided feedback of crop residue getting inside and jamming up the gauge wheel and opener. This spoked gauge wheel has shown exceptional performance within these areas as well. These wheels are compatible with both 90 Series openers on seeding tools and planter row-units.

Below is a chart that demonstrates a competitive advantage over MudSmith™ wheels for mud and residue flow:

| MudSmith | John Deere | Percent improvement | |

| Open area | 329 cm2 (51 cu in.) | 471 cm2 (73 cu in.) | 43 percent |

| Rim height | 1.9 cm (3/4 in.) | 1.4 cm (9/16 in.) | 25 percent |

| Spoke width | 3.5 cm (1-3/8 in.) | 1.9 cm (3/4 in.) | 45 percent |

The wheel is serviceable along with other parts.

- AA86055 – complete wheel assembly

- A101570 – inner wheel rim half

- A101571 – outer wheel rim half

Not compatible in dual gauge wheel applications.

MudSmith is a trademark of MudSmith, LLC.

Specs & Compare

Key Specs | 1590 Current Model |

| Working width | 4.57 m 15 ft |

| Total weight empty | 3837.4 kg 8460 lb |

| Capacities | Plain grain 1850.1 L 52.5 bu Grain/Fertilizer 2026.2 L 57.5 bu |

| Opener assembly | Spacing 19.1/38.1/50.8 cm 7.5/15/20 in. |

Dimensions | |

| Working width | 4.57 m 15 ft |

| Transport width | 4.65 m 15.25 ft, in. |

| Transport height | 2.08 m 6.83 ft, in. |

| Overall length | With wheels - 6.1 m 20 ft |

| Total weight empty | 3837.4 kg 8460 lb |

| Hitch weight empty | 1406.1 kg 3100 lb |

| Hitch weight full | 2041.2 kg 4500 lb |

| Clearance | Road opener - 20.3 cm 8 in. |

Capacities | |

| Plain grain | 1850.1 L 52.5 bu |

| Grain/Fertilizer | 2026.2 L 57.5 bu |

Meters | |

| Type | Fluted-feed |

Opener assembly | |

| Number of openers | 18 or 24 |

| Spacing | 19.1/38.1/50.8 cm 7.5/15/20 in. |

| Down pressure | Active hydraulic down pressure per opener - 75 to 204 kg 165 to 450 lb |

| Disk | At a 7-degree angle - 45.7 cm 18 in. |

| Gauge wheels | 11.4 x 40.6 cm 4.5 x 16 in. |

| Press wheels | 2.54 x 25.4 cm 1 x 10 in. |

| Closing wheels | 2.54 x 30.5 cm 1 x 12 in. |

Tractor requirements | |

| Hydraulic requirements | One selective control valve (SCV) |

| Electrical requirements | Seven-pin connection |

Additional information | |

| Date collected | |

Monitor | |

| Type |